Gefran sensor metal plate rolling process

Gefran is supply by Jon&Jul Automation Vietnam.

In the metal plate rolling process, it is extremely important to control the main process parameters, such as roll position and oil pressure and temperature. Gefran is a ideal partner because it offers a complete range of sensors, from position to temperature, to satisfy the customer’s needs.

Plate rolling is an industrial process in which metal sheets are run through rollers in a circular trajectory and maintain a set radius of curvature. There may be three or four rolls, in parallel axes, whose reciprocal position is controlled. In this way, metal sheets or profiles can be cold-rolled to obtain conical or cylindrical curves. The two external rolls, adjustable in position, roll the bottom of the material while the internal roll (normally in a fixed position) presses the top.

On machines with three adjustable rolls, the top roll moves vertically while the two side rolls move horizontally and independently. With this special design, the distance between points of curvature can be set as required, according to the same principle used with a variable V die.

One of the main demands of plate roll manufacturers is perfect control of sheets to minimize the distance between points of curvature. It is essential to check the radius of curvature and the parallelism of the rolls, controlled by measuring roll shift with a precision of 0.05 mm.

Various types of sensors were installed on the roll to measure position, pressure, and temperature.

Linear displacement transducers, installed outside the machine, are used to precisely control distance and parallelism between the rolls.

The choice of the PC-M/PZ-34 series (potentiometers) or the MK4/IK4 series (magnetostrictives) depends on the degree of precision required and on performance in terms of IP rating.

Specifically, the potentiometer series has non-linearity values of 0.05% FS, while the magnetostrictive series achieves values of 0.01% FS.

The MK4/IK4 magnetostrictive series is rated IP67, while the PC-M/PZ-34 series is rated IP65.

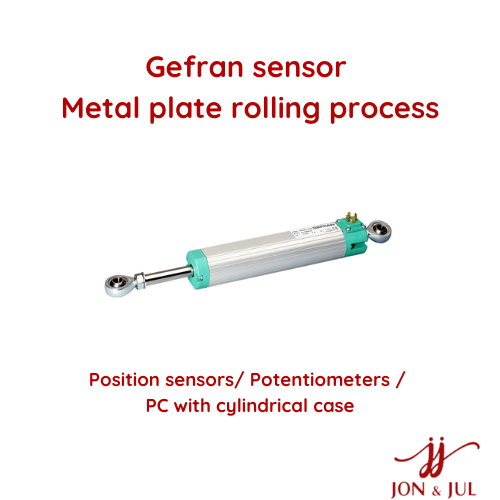

Metal plate rolling process Gefran Position sensors/ Potentiometers / PC with cylindrical case

- 50 to 750 mm stroke

- Mechanical fixing and selfaligning linkage using 2 ball-joints

- Maximum angular movement up to ± 30°

- Independent linearity ± 0.05%

- Repetibility 0.01 mm

- Infinite resolution

- No variation of electrical signal outside theoretical electrical stroke

- Displacement speed up to 5 m/s

- Working temperature: -30…+100°C

- Electrical connections:

- PC H 3-pole connector

- PC M 4-pole connector to standard DIN43650-ISO4400

- PC B 5-pole connector (DIN43322)

- PC F 3-pole screened cable (1 m length)

- Life duration: > 25×106 meters or > 100×106 operations, whichever is the smaller (within C.E.U.)

- Grade of protection IP65

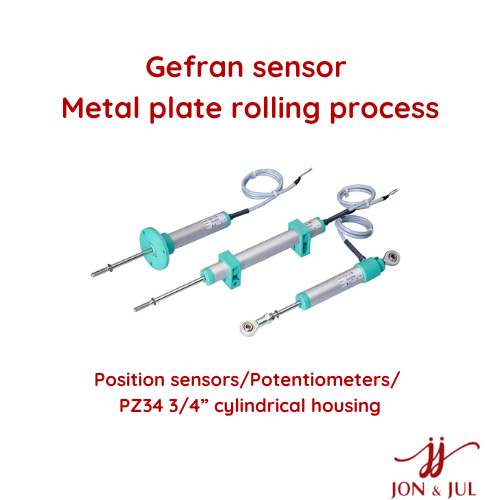

Metal plate rolling process Gefran Position sensors/Potentiometers/ PZ34 3/4” cylindrical housing

- 25 to 300 mm stroke

- Mechanical fixing using brackets, selfaligning ball-joints or flange

- Independent linearity up to ± 0.05%

- Infinite resolution

- No variation of electrical signal outside theoretical electrical stroke

- Displacement speed 10 m/s

- Working temperature: -30…+100°C

- Electrical connection: 3-pole screened cable (1m length)

- Life duration: > 25×106 meters or >100×106 operations, whichever is the smaller (within C.E.U.)

- Grade of protection IP60

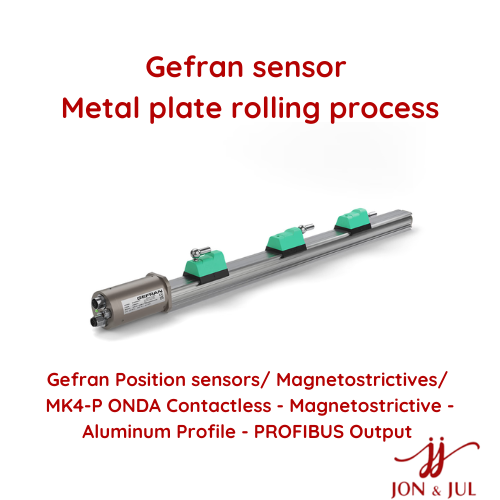

Metal plate rolling process Gefran Position sensors/ Magnetostrictives/ MK4-P ONDA Contactless - Magnetostrictive - Aluminum Profile - PROFIBUS Output –

- ONDA technology

- Stroke: 50 to 4000mm

- Position resolution settable via software up to 1 μm

- Speed resolution up to 0.25 mm/sec

- Conforms to CE directives (EN 50081-1 50082-1)

- Vibration-resistant (DIN IEC68T2/6 12 g)

- IP67 protection rating

- Controls up to four cursors simultaneously

- Two M12 connectors for simplified connection to Profibus and one M8 connector for separate connection to power supply (transducer can be powered without having to be connected to bus)

- Local intelligence

- Profibus DPV0 interface on RS485 in conformity to IEC 61158

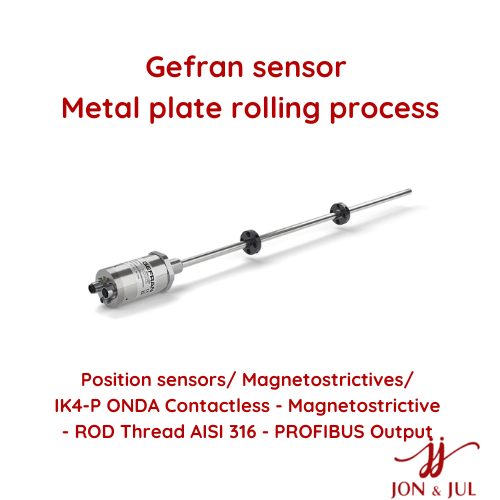

Metal plate rolling process Gefran Position sensors/ Magnetostrictives/ IK4-P ONDA Contactless - Magnetostrictive - ROD Thread AISI 316 - PROFIBUS Output –

- ONDA technology

- Stroke: 50 to 4000mm

- Position resolution settable via software up to 1 μm

- Speed resolution up to 0.25 mm/sec

- Conforms to CE directives (EN 50081-1 50082-1)

- Vibration-resistant (DIN IEC68T2/6 12 g)

- IP67 protection rating

- Controls up to four cursors simultaneously

- Two M12 connectors for simplified connection to Profibus and one M8 connector for separate connection to power supply (transducer can be powered without having to be connected to bus)

- Local intelligence

- Profibus DPV0 interface on RS485 in conformity to IEC 61158

Metal plate rolling process Gefran Pressure sensors / KS Compact size SIL2 Volt or mA outputs

The pressure transmitters measure the hydraulic pressure of the entire machine and, in particular, thrust pressure on the rolls.

The KS series of pressure transmitters, built with thick film technology on stainless steel, is accurate, robust, and compact, offering significant added value in terms of functional safety. The KS series has SIL2 certification.

- Ranges: from 1 to 1000 bar

- Nominal Output Signal: 0…10Vdc (3 wires / 4…20mA (2 wires)

- Compact size

- Wetted parts: Stainless steel

- SIL 2 certified according to IEC/EN 62061:2005

- cULus certification available

Plate feed is managed by the encoder, which controls plate rotation. Specifically, the EG02 series encoder acts as a sensor to check slipping.

Metal plate rolling process Gefran Temperature sensors/ Resistance thermometers/ AR6M MgO amplified output - General purpose

The AR6M series temperature sensors keep oil temperature under control in the hydraulic power unit. This extremely reliable component is a PT100 resistance thermometer built with mineral oxide (MgO) technology and has a 4-20mA amplified outx put signal.

- 4…20mA Transmitter

- Amplified output signal

- Temperature limits: – 200 … + 600° C

- Tolerance: UNI 7937, IEC 751 standards:

- ± 0.15° C a 0° C for class A (1/2 DIN)

- ± 0.30° C a 0° C for class B (1 DIN)

- ± 0.10° C a 0° C for 1/3 DIN class

- Compact mineral insulated (MgO) resistance thermometer element (Pt100 at 0°C) and continuous metal sheath

- Application versatility

For more Gefran products, please click here

Follow our Facebook: Jon&Jul VietNam

Please feel free to contact me:

Ms. Trinh

Hotline: 094.103.5500

Email: trinh@jon-jul.com