Gefran Sensor Plastic Industry

Gefran is supply by Jon&Jul Automation Vietnam.

Plastic molding machines

The injection molding process has a high number of physical parameters that must be conditioned in order to obtain an excellent price/performance ratio, and can create very complex products with extremely precise details.

Plastic is heated to the melting point and then injected under pressure into a closed mold to fill the entire cavity. The plastic is then cooled so that it solidifies, after which the mold is opened and the product is extracted.

Gefran is the perfect partner: a specialist with years of experience in the design and manufacture of transducers to measure main physical parameters as position, pressure and temperature.

Plastic Industry Gefran Position sensors/ Potentiometers/ PK Rodless

To ensure precise control of injection screw movements, the PK rodless (cursor-type) rectilinear displacement transducer. Its compact, rodless design offers versions with very long strokes.

- The transducer has been improved in order to guarantee greater reliability under all conditions

- Mechanical linkage using joint with take up of play, M5 thread

- Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke

- The new grooves provide an excellent alternative to the usual system of fastening with brackets

- Ideal for applications on plastic injection presses, vertical presses, and on many other processing

- Grade of protection IP40

Plastic Industry Gefran Position sensors/ Potentiometers/ LT with Shaft

To control the movement of the injection unit and of mold opening/closing, an LT series is installed displacement transducer, offering proven technology, easy installation, robustness, reliability, and high resolution (0.01 mm even in extreme conditions).

- The transducer has been improved in order to guarantee greater reliability under all conditions

- A sturdier structure makes the LT series even stronger for applications with heavy vibration

- Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke

- The new grooves provide an excellent alternative to the usual system of fastening with brackets

- Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines

|

Cảm biến vị trí: Code: LT-M-0450-S-XL0202 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Code: LT-M-0375-S-XL0202 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Code: LT-M-0300-S-XL0202 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Code: LT-M-0150-S 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Model: LT-M-0100-S-XL0202 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Model: LT-M-0200-S-XL0202 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Model: LT-M-0300-S-XL0202 0000X000X00 |

Gefran |

|

Cảm biến vị trí: Model: LT-M-0400-S-XL0202 0000X000X00 |

Gefran |

Plastic Industry Gefran Pressure sensors/ TPSA High accuracy Volt or mA output

Plastic Industry Gefran sensor TPSA extensimetric transducer to control hydraulic pressure.

With guaranteed robustness and high accuracy (±0.1% FS), the TPSA is one of Gefran’s most suitable products for this type of application, which requires measurement in a very harsh environment with dust, strong vibrations and high temperatures.

- Ranges from: 0…50 bar to 0…1000 bar (from 0…750 to 0…15000 psi)

- Accuracy: ±0.1% FSO typical

- Complete range of voltage/current outputs

- Stainless steel construction

- Protection rating: IP65 / IP67

- Wetted parts: 17-4 PH

- Operating temperature range: -40…+105°C

- Accessories: TDP

Plastic Industry Gefran Temperature sensors/ Thermocouples/ TC1

To map temperatures in key zones, thermocouples is installed, specifically designed for the plastics processing industry.

- Max. temperature limit: -40…+250°C (see table for thermocouple cable used)

- Reference tolerances: Standards IEC 584.2 class 2 for type J, K: ± 2.5°C (-40…+333°C)

- Cable to DIN standard

- Highly versatile

- Low cost

|

Cặp nhiệt điện:Model: TC1-B-3-K-5-A-I-B-1-50-B-000-G-300-X-X |

Gefran |

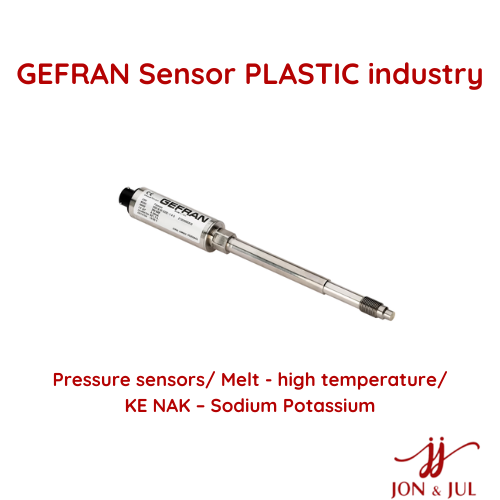

Plastic Industry Gefran sensor Pressure sensors/ Melt - high temperature/ KE NAK – Sodium Potassium - Output 4…20Ma

the KE series of Melt pressure transducers is used on its extrusion lines, which grant optimized extrusion processes thanks to their ability to keep a stable and optimal flow-state, allowing for better performances and safety standards. These sensors can measure pressure even at intense temperatures of 538 °C and their GTP+ coating vastly improves resistance to corrosion and abrasion. Their hydraulic pressure signal transmission utilizes an incompressible medium (NaK – sodium/potassium), which ensures stable temperatures.

- Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi

- Accuracy: < ±0.25% FS (H); < ±0.5% FS (M)

- Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS)

- Quantity of NaK contained per model: KE0 series (30mm3) (0.00183 in3), KE1, KE2, KE3 (40mm3) (0.00244 in3)

- 1/2-20UNF, M18x1.5 standard threads; other types available on request

- Autozero function on board / external option

- Stem drift Autocompensation function (SP version)

- Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F)

- 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F)

- Hastelloy C276 diaphragm for temperatures up to 300°C (570°F)

- 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi

|

Cảm biến áp suất: Code: KE0-7-M-B07C-1-4-0-S-P-E-D70 2130B000X00 |

For more Gefran products, please click here

Follow our Facebook: Jon&Jul VietNam

Please feel free to contact me:

Ms. Trinh

Hotline: 094.103.5500

Email: trinh@jon-jul.com