ADF280 Alia Viet Nam

Price: Contact

Brand: Alia

Category: Flow Meter

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Electronic

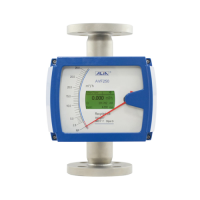

V-cone flowmeter ADF280 Alia Vietnam

Introducing the V-cone flowmeter ADF280 Alia Vietnam

ADF280 series V-cone flowmeter is a new type of orifice device based on the venturi tube measuring principle and combines the advantages of venturi tube, annular hole plate and wear-resistant hole plate. The sensor has a throttle cone structure with no stagnation zone and has liquid reshaping properties. Its edge is not easy to wear and can maintain long-term precision. There are many types of differential pressure transmitters for you to choose from such as APT9000, APT9500, APT9600. Due to the temperature and pressure compensation function, it can measure the flow of gas, steam, liquid, etc., and is widely used in process control and measurement in petroleum, chemical industry, metallurgy , electric power, heating and water supply.

Characteristics of V-cone flowmeter ADF280 Alia Vietnam

- High precision and repeatability, wide temperature and turnover rates and

- pressure compensation

- Max. The temperature is 500°C; max. Pressure is 100 bar

- Very wide size selection (15-3000 mm)

- Measurement of clean/dry liquids, slurries, gases and steam

- Multi-phase flow can be measured

- Less requirement for straight pipe spacing upstream and downstream Dirt-resistant, low pressure loss

- Insensitive to suspended contaminants

Technical specifications of V-cone flowmeter ADF280 Alia Vietnam

| Gas equipment | : | V-shaped cone |

| Process fluid | : | Liquid, gas, steam |

| Pipe diameter | : | 15…3000 mm (1/2"...120") |

| Measuring range | : | Liquid: 0-15 m/s |

| : | Gas/Steam: 0-45 m/s | |

| Reynolds number | : | 5×10 3 -1×10 7 |

| Ratio β | : | 0,45-0,85 |

| Accuracy | : | ±1.0% of reading |

| Repeatability | : | ±0.2% of reading |

| Initial rate | : | Higher than 10:1 |

| Operating pressure | : | DN1400 25 bar (Max. 200 °C) |

| : | DN300 ≤ 100 bar (Max. 200 °C) | |

| Temperature | : | -50~500°C |

| Ambient temperature | : | -25~80°C |

| Material | ||

| Cone | : | SS 304 / SS 316 |

| flange | : | Carbon Steel / SS 304 / SS 316 |

| Body | : | Carbon Steel / SS 304 / SS 316 |

| Pressure loss | : | β=0.45, Δω=0.74ΔP |

| : | β=0.55, Δω=0.61ΔP | |

| : | β=0.65, Δω=0.49ΔP | |

| : | β=0.75, Δω=0.36ΔP |

| Process connection | : | flange |

| Flange type | : | HE 10K / HE 20K / HE 40K |

| : | ANSI 150# / ANSI 300# / ANSI 600# | |

| : | DIN PN10 / PN16 / PN25 / PN40 | |

| Structure | : | Compact or remote |

| Setting | : | Horizontal |

| : | Straight | |

| Pressure faucet | : | Internal thread M20*1.5 (standard) |

| Pipeline requirements | : | 0-10D upstream and 0-5D downstream |

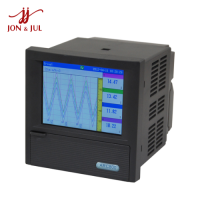

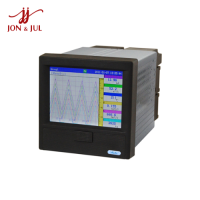

| Control system | : | APT9000, APT9500, APT9600 |

| Output current | : | 4-20 mA (2 wire) |

| with HART signal (Compatible) | ||

| Payload | : | Rohm=(VDC-9) * 50 |

| Protection class | : | IP67 |

| : | Intrinsic safety, Ex ia IIC T5 | |

| : | Explosion-proof, Ex d IIB T5 | |

| Accessory | ||

| Pressure transducer | : | Applicable for pressure compensation |

| Temperature probe | : | Applicable for temperature compensation |

| Flow calculator | : | AFC365 |

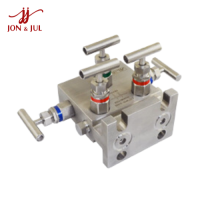

| By | : | 3-valve manifold or 5-valve manifold |

| Others | : | Isolation valve, condenser |