APT9600 Alia Viet Nam

Price: Contact

Brand: Alia

Category: Transmitter

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Electronic

Multivariable transmitter APT9600 Alia Vietnam

Introducing the APT9600 multivariable transmitter Alia Vietnam

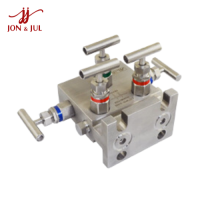

The APT9600 multivariable transmitter is adaptable and capable of multivariable measurements of differential pressure, static pressure, and process temperature. The generator includes the flow equations of steam, gas and liquid. The device is also designed with an integrated flow calculation feature for fully compensated mass flow measurement. Multivariable generators are designed to meet challenging processes.

Features of APT9600 Alia Vietnam multivariable transmitter

- The adapter can be rotated in 4 directions for easy installation

- Multiple variables Measurement, process streamlining and cost efficiency

- Full compensation for gas and steam measurements is available

- Liquid mass measurements can be density compensated by temperature

- Accuracy 0.075%

- Set parameters directly with the keyboard

- Output 4-20 mA, HART communication

- The transmitter allows measurement of multiple variables in combination of differential static pressure and temperature

Specifications of multivariable transmitter APT9600 Alia Vietnam

| Process fluid | : | Liquid, gas, steam |

| Application | : | Differential pressure, static pressure |

| Temperature, flow | ||

| DP range | : | 0-200 kPa |

| Pressure range | : | 0-25 MPa (0-250 bar) |

| Temperature | : | -25~500°C (-13°F ~ 932°F) RTD (PT1000) |

| Flow range | : | 0-999999 |

| Initial rate | : | 100:1 |

| Accuracy | : | +/- 0.075% of span |

| : | Type A (Temperature) | |

| The stability | : | +/- 0.15% of URLs for 2 years |

| Working temperature | : | -25~95°C |

| Ambient temperature | : | -25~70°C |

| Material | ||

| Flange/Adapter | : | 304 Stainless Steel / 316 Stainless Steel |

| Drains/vents | : | 304 Stainless Steel / 316 Stainless Steel |

| Diaphragm | : | 316L / Hastelloy C stainless steel |

| Wet O-ring | : | Buna N / Viton / PTFE |

| Fasteners | : | Carbon Steel/316 Stainless Steel |

| T. Sensor wet part | : | 316L / Hastelloy C stainless steel |

| Converter shell | : | Low copper cast aluminum alloy with |

| polyurethane, light blue paint | ||

| Fill with liquid | : | Silicone oil |

| Mount | : | Direct Mount/Bracket on 2" Pipe |

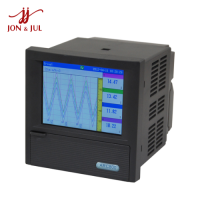

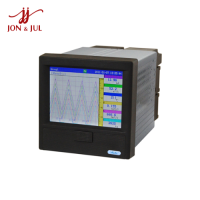

| Display | : | 8-digit totalizer, 6-digit line rate |

| : | Pressure 5 digits, Temperature 5 digits. | |

| Display unit | : | 32 Flow engineering units |

| Keyboard | : | 3 internal keys for programming |

| and output settings | ||

| Output current | : | 4-20 mA (2 wire) |

| with HART signal (Compatible) | ||

| Payload | : | Rohm= (VDC-12) * 50 |

| Power supply | : | 12-32 VDC |

| Shock Absorbers | : | 0-32 seconds |

| Humidity limit | : | Relative humidity 0-100% |

| Turn on time | : | 2 seconds with minimal damping |

| Zero calibration | : | Automatic zero point correction by push button |

| Enter the cable | : | Conduit Thread M20 / 1/2" NPT (Female) |

| Protection class | : | IP67 (Standard) |

| : | Intrinsically safe, Eex ia IIC T5 (Standard) | |

| : | Explosion-proof, Ex d IIB T5 (Optional) | |

| EMI/RFI effects | : | Monitor SAMA PMC 33.1 from 20-1000 MHz |

| and for field strengths up to 30 V/m | ||

| Vibration effect | : | +/- 0.05% URL per g to 200 Hz in any axis |

| Process connection | : | 1/4"-18NPT |

| : | 1/2"-14 NPT (with adapter) | |

| Size | : | 102mm(W) * 188mm(H) * 130mm(D) |

| Weight | : | 3,5 kg |