APT9500 Alia Viet Nam

Price: Contact

Brand: Alia

Category: Transmitter

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Electronic

Pressure flow transmitter APT9500 Alia Vietnam

Introducing the APT9500 Pressure Flow Transmitter Alia Vietnam

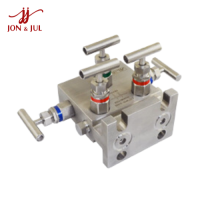

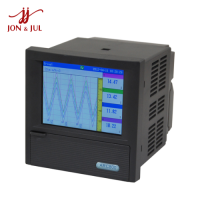

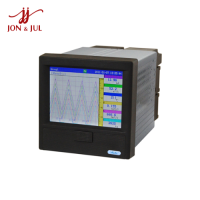

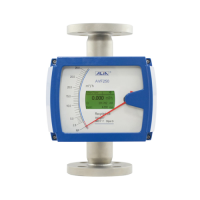

The APT9500 series is a differential pressure flow meter transmitter. Differential pressure can be converted into flow value through microcomputer technology and flow totalizer. Differential pressure can be displayed directly on the LCD screen. It is equipped with powerful output functions: 4-20 mA, pulse and HART. APT9500 is widely used in differential pressure sensor flowmeters such as orifice, venturi, annubar, v-cone, etc. It has high stability and high accuracy.

Features of Pressure Flow Transmitter APT9500 Alia Vietnam

- The adapter can rotate in six directions for easy installation

- Can display flow rate, totalizer and pressure difference at the same time

- Two years stable 0.2%

- Accuracy 0.075%

- Set parameters directly with the keyboard

- 4-20 mA and pulse output, HART communication

- Automatic zero point correction by push button

- Explosion and weather resistant housing

Technical specifications of APT9500 Pressure Flow Transmitter Alia Vietnam

| Process fluid | : | Liquid, gas, vapor |

| Application | : | Measure differential pressure flow |

| Pressure range | : | 0-2500 kPa |

| Flow range | : | 0-999999 |

| Initial rate | : | 20:1 |

| Accuracy | : | +/- 0.075% of span |

| The stability | : | +/- 0.15% of URLs for 2 years |

| Working temperature | : | -25~95°C |

| Max. Pressure | : | 40 MPa |

| Material | ||

| Flange/Adapter | : | 304 Stainless Steel / 316 Stainless Steel |

| Drains/vents | : | 304 Stainless Steel / 316 Stainless Steel |

| Diaphragm | : | 316L Stainless Steel / Hastelloy B / |

| Hastelloy C / Monel / Tantalum | ||

| Wet O-ring | : | Buna N / Viton / PTFE |

| Fasteners | : | Carbon Steel/316 Stainless Steel |

| Wireframe | : | Carbon Steel/Stainless Steel 304/316 |

| Name/Tag Table | : | 304 Stainless Steel / 316 Stainless Steel |

| Converter shell | : | Low copper cast aluminum alloy with |

| polyurethane, light blue paint | ||

| Fill with liquid | : | Silicone Oil / Fluorine Oil |

| Protection class | : | IP67 (Standard) |

| : | Intrinsically safe, Eex ia IIC T5 (Standard) | |

| : | Explosion-proof, Ex d IIB T5 (Optional) | |

| Mount | : | Direct Mount / Bracket on 2" Pipe |

| Display | : | 9-digit totalizer, 6-digit line rate |

| Display unit | : | 32 Flow engineering units |

| 5 programmable digits for special units | ||

| Keyboard | : | 3 internal keys for programming |

| and output settings | ||

| Output current | : | 4-20 mA (2 wire) |

| with HART signal (Compatible) | ||

| Payload | : | Rohm= (VDC-9) * 50 |

| Pulse output | : | Pulse rate |

| Power supply | : | 9-36 VDC |

| Shock Absorbers | : | 0-32 seconds |

| Humidity limit | : | Relative humidity 0-100% |

| Turn on time | : | 2 seconds with minimal damping |

| Zero calibration | : | Automatic zero point correction by push button |

| Enter the cable | : | Conduit Thread M20 / 1/2" NPT (Female) |

| Temperature effect | : | +/- 0.18% span above 20°C |

| Vibration effect | : | +/- 0.05% URL per g to 200 Hz in any axis |

| EMI/RFI effects | : | Monitor SAMA PMC 33.1 from 20-1000 MHz |

| and for field strengths up to 30 V/m | ||

| Process connection | : | 1/4-18NPT |

| : | 1/2-14 NPT (with adapter) | |

| Ambient temperature | : | -25~80°C |

| Size | : | 102 mm (W) * 188 mm (H) * 130 mm (D) |

| Weight | : | 3,5 kg |