MM25KS Mikipulley Viet Nam

Price: Contact

Brand: Mikipulley Viet Nam

Category: Industrial joints

Supplier: Jon&Jul Việt Nam

Origin: Japan

Ứng dụng sản phẩm: accessory, Automation equipment, Electronic, Industry, Mechanical

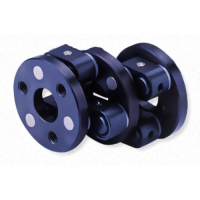

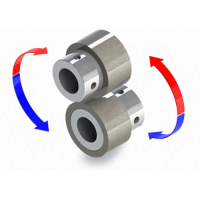

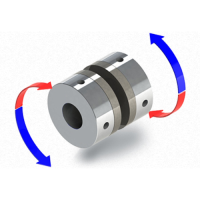

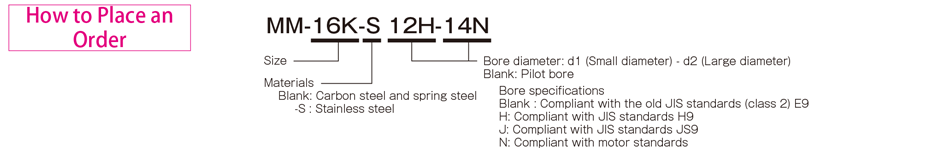

MM25KS MM Models Industrial Connectors, Couplings Mikipulley Vietnam

Introducing the MM25KS coupling Mikipulley Vietnam

MM model

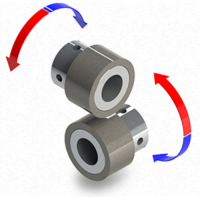

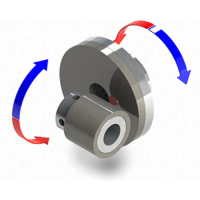

[Specifications]

| Model | Rated torque [N・m] | False | Max. rotation speed [min -1] | Torsional stiffness [N・m/rad] | Moment of inertia [kg・m 2] | Weight[kg] | ||

|---|---|---|---|---|---|---|---|---|

| Song song [mm] | Angle [°] | Shaft [mm] | ||||||

| MM-6K | 2,5 | 0,3 | 3 | +0,6 | 20000 | 143 | 7,65×10 -7 | 0,03 |

| MM-8K | 5 | 0,3 | 3 | +0,8 | 15000 | 286,5 | 4,08×10 -6 | 0,07 |

| MM-12K | 10 | 0,4 | 3 | +1,0 | 12000 | 573 | 1,43×10 -5 | 0,14 |

| MM-14K | 10 | 0,5 | 3 | +1,0 | 10000 | 573 | 2,47×10 -5 | 0,15 |

| MM-16K | 20 | 0,6 | 3 | +1,2 | 9000 | 1146 | 6,12×10 -5 | 0,30 |

| MM-19K | 20 | 0,7 | 3 | +1,2 | 8000 | 1146 | 8,42×10 -5 | 0,32 |

| MM-20K | 40 | 0,7 | 3 | +1,6 | 7000 | 2292 | 1,99×10 -4 | 0,70 |

| MM-24K | 40 | 0,9 | 3 | +1,6 | 7000 | 2292 | 2,63×10 -4 | 0,75 |

| MM-25K | 90 | 0,9 | 3 | +2.0 | 6000 | 3438 | 5,66×10 -4 | 1,25 |

| MM-28K | 90 | 1.0 | 3 | +2.0 | 6000 | 2865 | 5,77×10 -4 | 1,35 |

| MM-30K | 150 | 1.1 | 3 | +2,5 | 5000 | 4297,5 | 1,39×10 -4 | 2.10 |

| MM-35K | 220 | 1.2 | 3 | +3,2 | 4500 | 6303 | 3,01×10 -4 | 3,50 |

| Model | Rated torque [N・m] | False | Max. rotation speed [min -1] | Torsional stiffness [N・m/rad] | Moment of inertia [kg・m 2] | Weight[kg] | ||

|---|---|---|---|---|---|---|---|---|

| Song song [mm] | Angle [°] | Shaft [mm] | ||||||

| MM-6K-S | 2,5 | 0,3 | 3 | +0,6 | 20000 | 143 | 7,65×10 -7 | 0,03 |

| MM-8K-S | 5 | 0,3 | 3 | +0,8 | 15000 | 286,5 | 4,08×10 -6 | 0,07 |

| MM-12K-S | 10 | 0,4 | 3 | +1,0 | 12000 | 573 | 1,43×10 -5 | 0,14 |

| MM-16K-S | 20 | 0,6 | 3 | +1,2 | 9000 | 1146 | 6,12×10 -5 | 0,30 |

| MM-20K-S | 40 | 0,7 | 3 | +1,6 | 7000 | 2292 | 1,99×10 -4 | 0,70 |

| MM-25K-S | 90 | 0,9 | 3 | +2.0 | 6000 | 3438 | 5,66×10 -4 | 1,25 |

*Max. Rotation speed does not take into account dynamic balance.

*Moment of inertia and mass measured for maximum bore diameter.

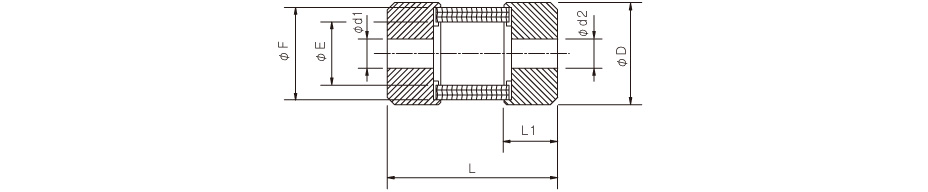

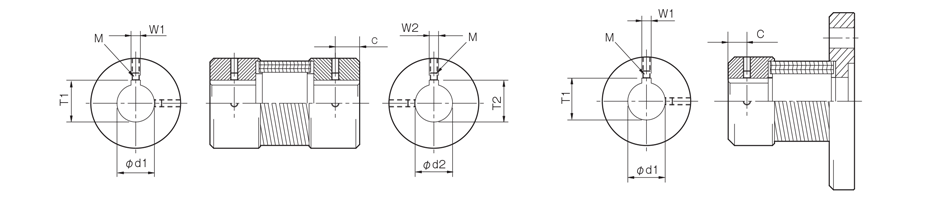

[Size]

| Model | d1, d2 | D | L | L1 | AND | F | ||

|---|---|---|---|---|---|---|---|---|

| pilot drill hole | Minimum. | Max. | ||||||

| MM-6K | 2,5 | 3 | 8 | 16 | 20 | 6 | 11 | 15,5 |

| MM-8K | 3,5 | 4 | 8 | 21 | 35 | 11 | 13 | 19 |

| MM-12K | 5,5 | 6 | 12 | 26 | 50 | 16,5 | 16,5 | 24 |

| MM-14K | 5,5 | 7 | 14 | 30 | 50 | 16,5 | 20,5 | 28 |

| MM-16K | 5,5 | 10 | 16 | 35 | 65 | 22 | 22,4 | 32 |

| MM-19K | 5,5 | 10 | 19 | 38 | 65 | 22 | 26,4 | 36 |

| MM-20K | 5,5 | 10 | 20 | 45 | 80 | 27 | 28 | 40 |

| MM-24K | 5,5 | 14 | 24 | 48 | 80 | 27 | 33 | 45 |

| MM-25K | 5,5 | 14 | 25 | 55 | 100 | 33,5 | 35 | 50 |

| MM-28K | 5,5 | 14 | 28 | 55 | 100 | 33,5 | 37 | 52 |

| MM-30K | 5,5 | 16 | 30 | 65 | 125 | 40 | 40,8 | 60 |

| MM-35K | 5,5 | 20 | 35 | 75 | 150 | 48 | 46 | 70 |

| Model | d1, d2 | D | L | L1 | AND | F | ||

|---|---|---|---|---|---|---|---|---|

| pilot drill hole | Minimum. | Max. | ||||||

| MM-6K-S | 2,5 | 3 | 8 | 17 | 25 | 9 | 11 | 15,5 |

| MM-8K-S | 3,5 | 4 | 8 | 21 | 35 | 11 | 13 | 19 |

| MM-12K-S | 5,5 | 6 | 12 | 26 | 50 | 16,5 | 16,5 | 24 |

| MM-16K-S | 5,5 | 10 | 16 | 35 | 65 | 22 | 22,4 | 32 |

| MM-20K-S | 5,5 | 10 | 20 | 45 | 80 | 27 | 28 | 40 |

| MM-25K-S | 5,5 | 14 | 25 | 55 | 100 | 32,5 | 35 | 50 |

* Pilot holes must be drilled into the part.

[Standard hole drilling standards]

| Models comply with the old JIS standard (type 2) JIS B 1301 1959 |

The models comply with the new JIS standard (H9) JIS B 1301 1996 |

Models comply with the new JIS standard (JS9) JIS B 1301 1996 |

Model conforms to JIS C 4210 2001 engine standard |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nominal hole diameter |

Hole diameter [d1・d2] |

Keyway width [W1・W2] |

Keyway height [T1・T2] |

Set screw hole [M] |

Nominal hole diameter |

Hole diameter [d1・d2] |

Keyway width [W1・W2] |

Keyway height [T1・T2] |

Set screw hole [M] |

Nominal hole diameter |

Hole diameter [d1・d2] |

Keyway width [W1・W2] |

Keyway height [T1・T2] |

Set screw hole [M] |

Nominal hole diameter |

Hole diameter [d1・d2] |

Keyway width [W1・W2] |

Keyway height [T1・T2] |

Set screw hole [M] |

| Tolerance H7,H8 |

Tolerance E9 |

- | Tolerance H7 |

Tolerance H9 |

- | Tolerance H7 |

JS9 Tolerance |

- | Tolerance G7,F7 |

Tolerance H9 |

- | ||||||||

| 4 | 4 +0,018 0 | - | - | 2-M3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 5 | 5 +0,018 0 | - | - | 2-M3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 6 | 6 +0,018 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 6:35 | 6,35 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 7 | 7 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 8 | 8 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 9 | 9 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 9,5 | 9,5 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 9,525 | 9,525 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 10 | 10 +0,022 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 11 | 11 +0,018 0 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 12 | 12 +0,018 0 | 4 +0,050 +0,020 | 13,5 +0,3 0 | 2-M4 | 12H | 12 +0,018 0 | 4 +0,030 0 | 13,8 +0,3 0 | 2-M4 | 12J | 12 +0,018 0 | 4 ±0,0150 | 13,8 +0,3 0 | 2-M4 | - | - | - | - | - |

| 14 | 14 +0,018 0 | 5 +0,050 +0,020 | 16,0 +0,3 0 | 2-M4 | 14H | 14 +0,018 0 | 5 +0,030 0 | 16,3 +0,3 0 | 2-M4 | 14Y | 14 +0,018 0 | 5 ±0,0150 | 16,3 +0,3 0 | 2-M4 | 14N | 14 +0,024 +0,006 | 5 +0,030 0 | 16,3 +0,3 0 | 2-M4 |

| 15 | 15 +0,018 0 | 5 +0,050 +0,020 | 17,0 +0,3 0 | 2-M4 | 15H | 15 +0,018 0 | 5 +0,030 0 | 17,3 +0,3 0 | 2-M4 | 15J | 15 +0,018 0 | 5 ±0,0150 | 17,3 +0,3 0 | 2-M4 | - | - | - | - | - |

| 16 | 16 +0,018 0 | 5 +0,050 +0,020 | 18,0 +0,3 0 | 2-M4 | 16H | 16 +0,018 0 | 5 +0,030 0 | 18,3 +0,3 0 | 2-M4 | 16J | 16 +0,018 0 | 5 ±0,0150 | 18,3 +0,3 0 | 2-M4 | - | - | - | - | - |

| 17 | 17 +0,018 0 | 5 +0,050 +0,020 | 19,0 +0,3 0 | 2-M4 | 17H | 17 +0,018 0 | 5 +0,030 0 | 19,3 +0,3 0 | 2-M4 | 17J | 17 +0,018 0 | 5 ±0,0150 | 19,3 +0,3 0 | 2-M4 | - | - | - | - | - |

| 18 | 18 +0,018 0 | 5 +0,050 +0,020 | 20,0 +0,3 0 | 2-M4 | 18H | 18 +0,018 0 | 6 +0,030 0 | 20,8 +0,3 0 | 2-M5 | 18J | 18 +0,018 0 | 6 ±0,0150 | 20,8 +0,3 0 | 2-M5 | - | - | - | - | - |

| 19 | 19 +0,021 0 | 5 +0,050 +0,020 | 21,0 +0,3 0 | 2-M4 | 19H | 19 +0,021 0 | 6 +0,030 0 | 21,8 +0,3 0 | 2-M5 | 19J | 19 +0,021 0 | 6 ±0,0150 | 21,8 +0,3 0 | 2-M5 | 19N | 19 +0,028 +0,007 | 6 +0,030 0 | 21,8 +0,3 0 | 2-M5 |

| 20 | 20 +0,021 0 | 5 +0,050 +0,020 | 22,0 +0,3 0 | 2-M4 | 20H | 20 +0,021 0 | 6 +0,030 0 | 22,8 +0,3 0 | 2-M5 | 20J | 20 +0,021 0 | 6 ±0,0150 | 22,8 +0,3 0 | 2-M5 | - | - | - | - | - |

| 22 | 22 +0,021 0 | 7 +0,061 +0,025 | 25,0 +0,3 0 | 2-M6 | 10 p.m | 22 +0,021 0 | 6 +0,030 0 | 24,8 +0,3 0 | 2-M5 | 22J | 22 +0,021 0 | 6 ±0,0150 | 24,8 +0,3 0 | 2-M5 | - | - | - | - | - |

| 24 | 24 +0,021 0 | 7 +0,061 +0,025 | 27,0 +0,3 0 | 2-M6 | 24H | 24 +0,021 0 | 8 +0,036 0 | 27,3 +0,3 0 | 2-M6 | 24J | 24 +0,021 0 | 8 ±0,0180 | 27,3 +0,3 0 | 2-M6 | 24N | 24 +0,028 +0,007 | 8 +0,036 0 | 27,3 +0,3 0 | 2-M6 |

| 25 | 25 +0,021 0 | 7 +0,061 +0,025 | 28,0 +0,3 0 | 2-M6 | 25H | 25 +0,021 0 | 8 +0,036 0 | 28,3 +0,3 0 | 2-M6 | 25J | 25 +0,021 0 | 8 ±0,0180 | 28,3 +0,3 0 | 2-M6 | - | - | - | - | - |

| 28 | 28 +0,021 0 | 7 +0,061 +0,025 | 31,0 +0,3 0 | 2-M6 | 28 hours | 28 +0,021 0 | 8 +0,036 0 | 31,3 +0,3 0 | 2-M6 | 28J | 28 +0,021 0 | 8 ±0,0180 | 31,3 +0,3 0 | 2-M6 | 28N | 28 +0,028 +0,007 | 8 +0,036 0 | 31,3 +0,3 0 | 2-M6 |

| 30 | 30 +0,021 0 | 7 +0,061 +0,025 | 33,0 +0,3 0 | 2-M6 | 30 hours | 30 +0,021 0 | 8 +0,036 0 | 33,3 +0,3 0 | 2-M6 | 30J | 30 +0,021 0 | 8 ±0,0180 | 33,3 +0,3 0 | 2-M6 | - | - | - | - | - |

| 32 | 32 +0,025 0 | 10 +0,061 +0,025 | 35,5 +0,3 0 | 2-M8 | 32H | 32 +0,025 0 | 10 +0,036 0 | 35,3 +0,3 0 | 2-M8 | 32J | 32 +0,025 0 | 10 ±0,0180 | 35,3 +0,3 0 | 2-M8 | - | - | - | - | - |

| 35 | 35 +0,025 0 | 10 +0,061 +0,025 | 38,5 +0,3 0 | 2-M8 | 35H | 35 +0,025 0 | 10 +0,036 0 | 38,3 +0,3 0 | 2-M8 | 35J | 35 +0,025 0 | 10 ±0,0180 | 38,3 +0,3 0 | 2-M8 | - | - | - | - | - |

* These standard hole drilling standards apply to BAUMANNFLEX MM/MF models.

* All standards starting from ø11 are the same as those in the old JIS standards column.

* The positions of the set screw and the keyway are not on the same plane.

* Screw set included with product.

* Positioning accuracy for keyway milling is determined by eye.

* Contact Miki Pulleys when the keyway requires positioning accuracy for a specific flange shaft.

* Refer to the technical documentation at the end of this volume for standard dimensions for borehole drilling in addition to those given here.

[Set screw position]

| Joint size | Distance C from edge [mm] |

|---|---|

| 6 | 3 |

| 8 | 5 |

| 12・14 | 7 |

| 16・19・20・24 | 10 |

| 25・28・30・35 | 15 |

See more technical documents here

See more technical products here

Link FaceBook Jon&Jul VietNam

-------------Communications Phone number: 0348097237 Email: Tu@jon-jul.com Address: No. 4, Street 14, Highway 13, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City, Vietnam.