SFH Models MikiPulley Viet Nam

Price: Contact

Brand: Mikipulley Viet Nam

Category: Industrial joints

Supplier: Jon&Jul Việt Nam

Origin: Japan

Ứng dụng sản phẩm: accessory, Automation equipment, Electronic, Industry, Mechanical

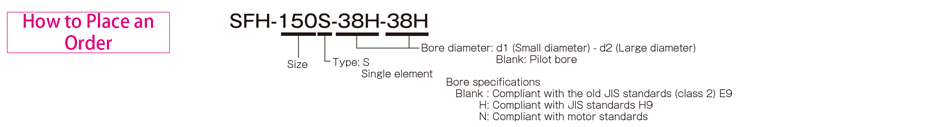

SFH Models Pulley articulated model MikiPulley Vietnam

Introducing SFH Models MikiPulley Vietnam

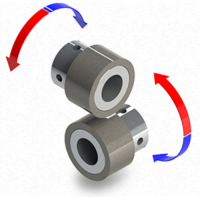

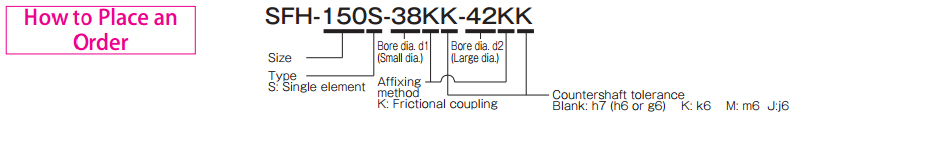

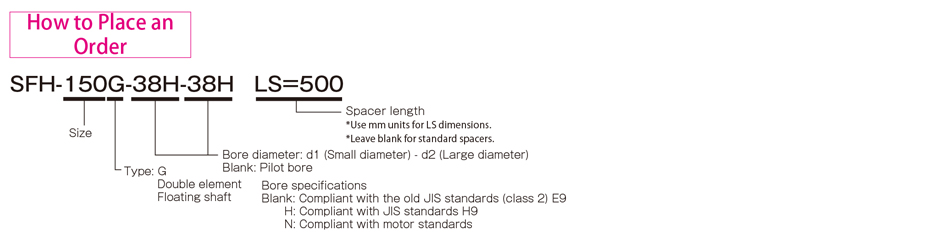

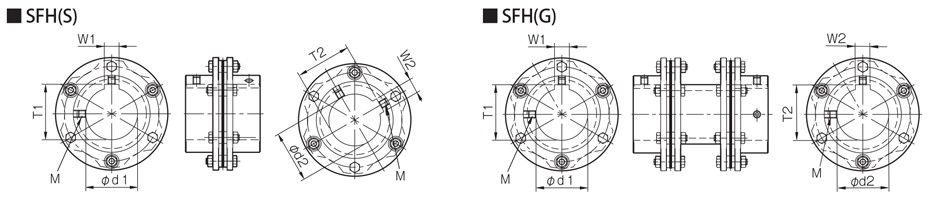

Types of SFH-□S

[Specifications] SFH-□S

| Model | Rated torque [N・m] | False | Max. rotation speed [min -1] | Torsional stiffness [N・m/rad] | Axial stiffness[N/mm] | Moment of inertia [kg・m 2] | Weight[kg] | |

|---|---|---|---|---|---|---|---|---|

| Angle [°] | Shaft [mm] | |||||||

| SFH-150S | 1000 | 1 | ±0,4 | 5900 | 1500000 | 244 | 12,60×10 -3 | 4,71 |

| SFH-170S | 1300 | 1 | ±0,5 | 5100 | 2840000 | 224 | 26,88×10 -3 | 7,52 |

| SFH-190S | 2000 | 1 | ±0,5 | 4700 | 3400000 | 244 | 43,82×10 -3 | 10,57 |

| SFH-210S | 4000 | 1 | ±0,55 | 4300 | 4680000 | 508 | 68,48×10 -3 | 13,78 |

| SFH-220S | 5000 | 1 | ±0,6 | 4000 | 5940000 | 448 | 102,53×10 -3 | 18h25 |

| SFH-260S | 8000 | 1 | ±0,7 | 3400 | 10780000 | 612 | 233,86×10 -3 | 29,66 |

*Max. Rotation speed does not take into account dynamic balance.

*Moment of inertia and mass measured for maximum bore diameter.

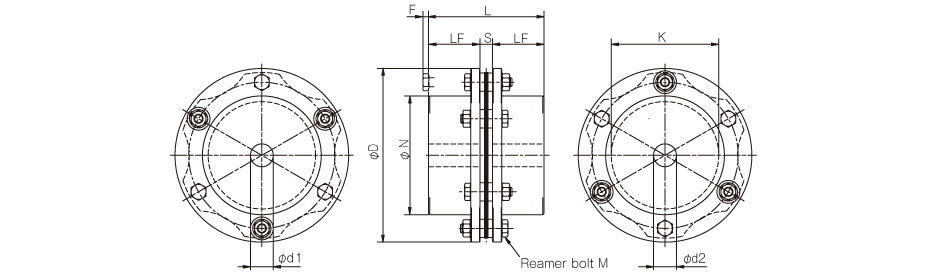

[Size] SFH-□S

| Model | d1, d2 | D | N | L | LF | S | F | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| pilot drill hole | Minimum. | Max. | |||||||||

| SFH-150S | 20 | 22 | 70 | 152 | 104 | 101 | 45 | 11 | 5 | 94 | 6-M8×36 |

| SFH-170S | 25 | 28 | 80 | 178 | 118 | 124 | 55 | 14 | 6 | 108 | 6-M10×45 |

| SFH-190S | 30 | 32 | 85 | 190 | 126 | 145 | 65 | 15 | 10 | 116 | 6-M12×54 |

| SFH-210S | 35 | 38 | 90 | 210 | 130 | 165 | 75 | 15 | 8 | 124 | 6-M16×60 |

| SFH-220S | 45 | 48 | 100 | 225 | 144 | 200 | 90 | 20 | -2 | 132 | 6-M16×60 |

| SFH-260S | 50 | 55 | 115 | 262 | 166 | 223 | 100 | 23 | 11 | 150 | 6-M20×80 |

* Pilot holes must be drilled into the part. See standard borehole drilling standards for information on borehole drilling.

*If you require a product with LS dimensions exceeding the above dimensions, please contact Miki Pulley with your required dimensions [mm]. Please contact Miki Pulley for assistance if the LS size is smaller than the above size or if LS ≧ 1000.

* The nominal diameter of a bored bolt is equal to the quantity minus the nominal diameter of the screw thread multiplied by the nominal length.

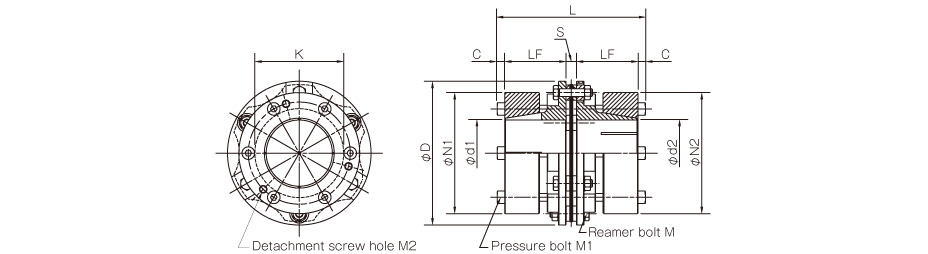

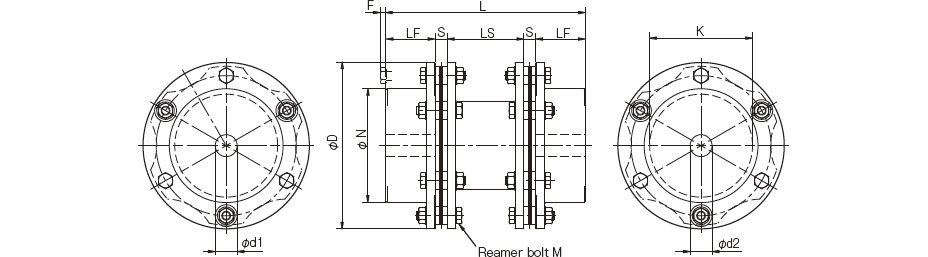

[Specifications] SFH-□S-□K-□K

| Model | Rated torque [N・m] | False | Max. rotation speed [min -1] | Torsional stiffness [N・m/rad] | Axial stiffness[N/mm] | Moment of inertia [kg・m 2] | Weight[kg] | |

|---|---|---|---|---|---|---|---|---|

| Angle [°] | Shaft [mm] | |||||||

| SFH-150S | 1000 | 1 | ±0,4 | 5900 | 1500000 | 244 | 25,14×10 -3 | 8,95 |

| SFH-170S | 1300 | 1 | ±0,5 | 5100 | 2840000 | 224 | 47,90×10 -3 | 12.53 |

| SFH-190S | 2000 | 1 | ±0,5 | 4700 | 3400000 | 244 | 60,40×10 -3 | 14.21 |

| SFH-210S | 4000 | 1 | ±0,55 | 4300 | 4680000 | 508 | 80,50×10 -3 | 16.12 |

*Max. Rotation speed does not take into account dynamic balance.

*The moment of inertia and mass in the table are measured for maximum bore diameter.

[Size] SFH-□S-□K-□K

| Model | D | L | d1, d2 | N1, N2 | LF | S | C | K | M | M1 | M2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SFH-150S | 152 | 157 | 38, 40, 42, 45, 48, 50 | 108 | 65 | 11 | 8 | 94 | 6-M8×36 | 6-M8×60 | 3-M8 |

| 55, 56, 60, 65, 70 | 128 | ||||||||||

| SFH-170S | 178 | 160 | 38, 40, 42, 45, 48, 50 | 108 | 65 | 14 | 8 | 108 | 6-M10×45 | 6-M8×60 | 3-M8 |

| 55, 56, 60, 65, 70 | 128 | ||||||||||

| 75, 80 | 148 | ||||||||||

| SFH-190S | 190 | 175 | 38, 40, 42, 45, 48, 50 | 108 | 70 | 15 | 10 | 116 | 6-M12×54 | 6-M10×65 | 3-M10 |

| 55, 56, 60, 65, 70 | 128 | ||||||||||

| 75, 80, 85 | 148 | ||||||||||

| SFH-210S | 210 | 181 | 38, 40, 42, 45, 48, 50 | 108 | 73 | 15 | 10 | 124 | 6-M16×60 | 6-M10×65 | 3-M10 |

| 55, 56, 60, 65, 70 | 128 | ||||||||||

| 75, 80, 85, 90 | 148 |

* The nominal diameter of each bolt and tap is equal to the quantity minus the nominal diameter of the screw thread multiplied by the nominal length. The quantities for the pressure bolt M1 and the loose screw hole M2 are the quantities for the shaft on one side.

[Combination of standard bore diameters]

| Model | Standard hole diameter d1, d2 [mm] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | |

| SFH-150S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| SFH-170S | 1100 | 1200 | 1250 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| SFH-190S | 1800 | 1900 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| SFH-210S | 1800 | 1900 | 2000 | 2150 | 2300 | 2400 | 2600 | 2650 | 2850 | 3100 | 3350 | 3600 | 3800 | ● | ● |

*Bore diameters marked with ● or numbers are supported as standard bore diameters.

*The bore diameter field contains numbers that are limited in the rated torque by the holding capacity of the shaft connection because of the small bore diameter. The numbers represent the rated torque value [N·m].

[Standard hole drilling standards]

| Models comply with the old JIS standard (type 2) JIS B 1301 1959 | The models comply with the new JIS standard (H9) JIS B 1301 1996 | Model conforms to JIS C 4210 2001 engine standard | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal hole diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) | Nominal hole diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) | Nominal hole diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) |

| ToleranceH7 | ToleranceE9 | -- | -- | ToleranceH7 | ToleranceH9 | -- | -- | ToleranceG7, F7 | ToleranceH9 | -- | -- | |||

| 22 | 22 +0,021 0 | 7 +0,061 +0,025 | 25,0 +0,3 0 | 2-M6 | 10 p.m | 22 +0,021 0 | 6 +0,030 0 | 24,8 +0,3 0 | 2-M5 | -- | -- | -- | -- | -- |

| 24 | 24 +0,021 0 | 7 +0,061 +0,025 | 27,0 +0,3 0 | 2-M6 | 24H | 24 +0,021 0 | 8 +0,036 0 | 27,3 +0,3 0 | 2-M6 | 24N | 24 +0,028 +0,007 | 8 +0,036 0 | 27,3 +0,3 0 | 2-M6 |

| 25 | 25 +0,021 0 | 7 +0,061 +0,025 | 28,0 +0,3 0 | 2-M6 | 25H | 25 +0,021 0 | 8 +0,036 0 | 28,3 +0,3 0 | 2-M6 | -- | -- | -- | -- | -- |

| 28 | 28 +0,021 0 | 7 +0,061 +0,025 | 31,0 +0,3 0 | 2-M6 | 28 hours | 28 +0,021 0 | 8 +0,036 0 | 31,3 +0,3 0 | 2-M6 | 28N | 28 +0,028 +0,007 | 8 +0,036 0 | 31,3 +0,3 0 | 2-M6 |

| 30 | 30 +0,021 0 | 7 +0,061 +0,025 | 33,0 +0,3 0 | 2-M6 | 30 hours | 30 +0,021 0 | 8 +0,036 0 | 33,3 +0,3 0 | 2-M6 | -- | -- | -- | -- | -- |

| 32 | 32 +0,025 0 | 10 +0,061 +0,025 | 35,5 +0,3 0 | 2-M8 | 32H | 32 +0,025 0 | 10 +0,036 0 | 35,3 +0,3 0 | 2-M8 | -- | -- | -- | -- | -- |

| 35 | 35 +0,025 0 | 10 +0,061 +0,025 | 38,5 +0,3 0 | 2-M8 | 35H | 35 +0,025 0 | 10 +0,036 0 | 38,3 +0,3 0 | 2-M8 | -- | -- | -- | -- | -- |

| 38 | 38 +0,025 0 | 10 +0,061 +0,025 | 41,5 +0,3 0 | 2-M8 | 38H | 38 +0,025 0 | 10 +0,036 0 | 41,3 +0,3 0 | 2-M8 | 38N | 38 +0,050 +0,025 | +0,036 010 | 41,3 +0,3 0 | 2-M8 |

| 40 | 40 +0,025 0 | 10 +0,061 +0,025 | 43,5 +0,3 0 | 2-M8 | 40H | 40 +0,025 0 | 12 +0,043 0 | 43,3 +0,3 0 | 2-M8 | -- | -- | -- | -- | -- |

| 42 | 42 +0,025 0 | 12 +0,061 +0,025 | 45,5 +0,3 0 | 2-M8 | 42H | 42 +0,025 0 | 12 +0,043 0 | 45,3 +0,3 0 | 2-M8 | 42N | 42 +0,050 +0,025 | 12 +0,043 0 | 45,3 +0,3 0 | 2-M8 |

| 45 | 45 +0,025 0 | 12 +0,061 +0,025 | 48,5 +0,3 0 | 2-M8 | 45H | 45 +0,025 0 | 14 +0,043 0 | 48,8 +0,3 0 | 2-M10 | -- | -- | -- | -- | -- |

| 48 | 48 +0,025 0 | 12 +0,061 +0,025 | 51,5 +0,3 0 | 2-M8 | 48H | 48 +0,025 0 | 14 +0,043 0 | 51,8 +0,3 0 | 2-M10 | 48N | 48 +0,050 +0,025 | 14 +0,043 0 | 51,8 +0,3 0 | 2-M10 |

| 50 | 50 +0,025 0 | 12 +0,061 +0,025 | 53,5 +0,3 0 | 2-M8 | 50H | 50 +0,025 0 | 14 +0,043 0 | 53,8 +0,3 0 | 2-M10 | -- | -- | -- | -- | -- |

| 55 | 55 +0,030 0 | 15 +0,075 +0,032 | 60,0 +0,3 0 | 2-M10 | 55H | 55 +0,030 0 | 16 +0,043 0 | 59,3 +0,3 0 | 2-M10 | 55N | 55 +0,060 +0,030 | 16 +0,043 0 | 59,3 +0,3 0 | 2-M10 |

| 56 | 56 +0,030 0 | 15 +0,075 +0,032 | 61,0 +0,3 0 | 2-M10 | 56H | 56 +0,030 0 | 16 +0,043 0 | 60,3 +0,3 0 | 2-M10 | -- | -- | -- | -- | -- |

| 60 | 60 +0,030 0 | 15 +0,075 +0,032 | 65,0 +0,3 0 | 2-M10 | 60H | 60 +0,030 0 | 18 +0,043 0 | 64,4 +0,3 0 | 2-M10 | 60N | 60 +0,060 +0,030 | 18 +0,043 0 | 64,4 +0,3 0 | 2-M10 |

| 65 | 65 +0,030 0 | 18 +0,075 +0,032 | 71,0 +0,3 0 | 2-M10 | 65H | 65 +0,030 0 | 18 +0,043 0 | 69,4 +0,3 0 | 2-M10 | 65N | 65 +0,060 +0,030 | 18 +0,043 0 | 69,4 +0,3 0 | 2-M10 |

| 70 | 70 +0,030 0 | 18 +0,075 +0,032 | 76,0 +0,3 0 | 2-M10 | 70H | 70 +0,030 0 | 20 +0,052 0 | 74,9 +0,5 0 | 2-M10 | -- | -- | -- | -- | -- |

| 75 | 75 +0,030 0 | 20 +0,092 +0,040 | 81,0 +0,5 0 | 2-M10 | 75H | 75 +0,030 0 | 20 +0,052 0 | 79,9 +0,5 0 | 2-M10 | 75N | 75 +0,060 +0,030 | 20 +0,052 0 | 79,9 +0,5 0 | 2-M10 |

| 80 | 80 +0,030 0 | 20 +0,092 +0,040 | 86,0 +0,5 0 | 2-M10 | 80H | 80 +0,030 0 | 22 +0,052 0 | 85,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

| 85 | 85 +0,035 0 | 24 +0,092 +0,040 | 93,0 +0,5 0 | 2-M12 | 85H | 85 +0,035 0 | 22 +0,052 0 | 90,4 +0,5 0 | 2-M12 | 85N | 85 +0,071 +0,035 | 22 +0,052 0 | 90,4 +0,5 0 | 2-M12 |

| 90 | 90 +0,035 0 | 24 +0,092 +0,040 | 98,0 +0,5 0 | 2-M12 | 90H | 90 +0,035 0 | 25 +0,052 0 | 95,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

| 95 | 95 +0,035 0 | 24 +0,092 +0,040 | 103,0 +0,5 0 | 2-M12 | 95H | 95 +0,035 0 | 25 +0,052 0 | 100,4 +0,5 0 | 2-M12 | 95N | 95 +0,071 +0,035 | 25 +0,052 0 | 100,4 +0,5 0 | 2-M12 |

| 100 | 100 +0,035 0 | 28 +0,092 +0,040 | 109,0 +0,5 0 | 2-M12 | 100H | 100 +0,035 0 | 28 +0,052 0 | 106,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

| 115 | 115 +0,035 0 | 32 +0,112 +0,050 | 125,0 +0,5 0 | 2-M12 | 115H | 115 +0,035 0 | 32 +0,052 0 | 122,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

* The positions of the set screw and the keyway are not on the same plane.

* Screw set included with product.

* Positioning accuracy for keyway milling is determined by eye.

* Contact Miki Pulleys when the keyway requires positioning accuracy for a specific flange shaft.

* Refer to the technical documentation at the end of this volume for standard dimensions for borehole drilling in addition to those given here.

[Set screw position]

| Model | Distance from edge[mm] |

|---|---|

| SFH-150 | 15 |

| SFH-170 | 20 |

| SFH-190 | 25 |

| SFH-210 | 30 |

| SFH-220 | 35 |

| SFH-260 | 40 |

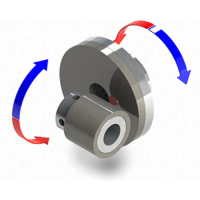

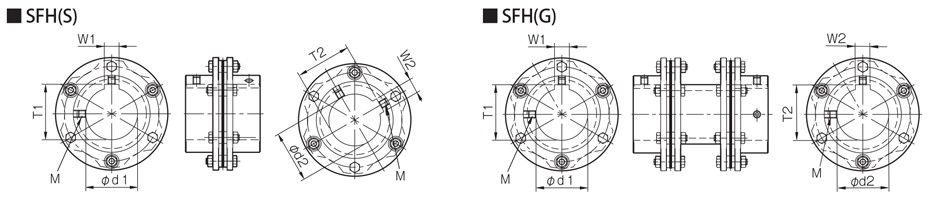

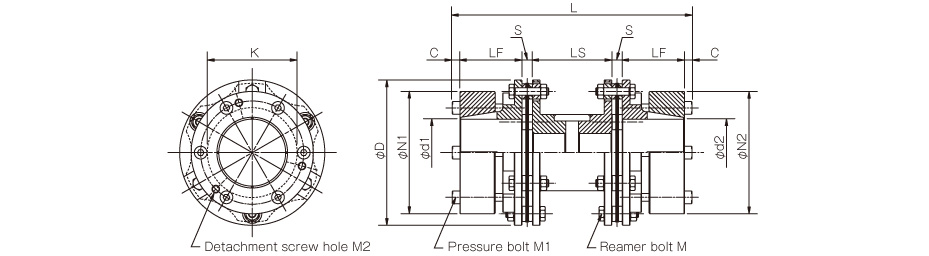

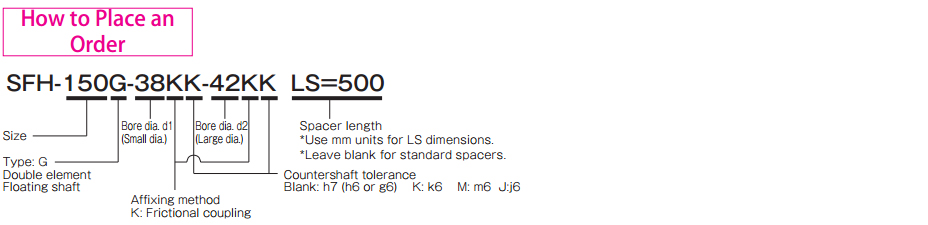

Types of SFH-□G

[Specifications] SFH-□G

| Model | Rated torque [N・m] | False | Max. rotation speed [min -1] | Torsional stiffness [N・m/rad] | Axial stiffness[N/mm] | Moment of inertia [kg・m 2] | Weight[kg] | ||

|---|---|---|---|---|---|---|---|---|---|

| Song song [mm] | Angle [°] | Shaft [mm] | |||||||

| SFH-150G | 1000 | 1.4 | 1 (On one side) | ±0,8 | 5900 | 750000 | 122 | 21,87×10 -3 | 8,72 |

| SFH-170G | 1300 | 1.6 | 1 (On one side) | ±1,0 | 5100 | 1420000 | 112 | 51,07×10 -3 | 13,94 |

| SFH-190G | 2000 | 2.0 | 1 (On one side) | ±1,0 | 4700 | 1700000 | 122 | 81,58×10 -3 | 19.51 |

| SFH-210G | 4000 | 2.1 | 1 (On one side) | ±1,1 | 4300 | 2340000 | 254 | 125,50×10 -3 | 24,26 |

| SFH-220G | 5000 | 2.3 | 1 (On one side) | ±1,2 | 4000 | 2970000 | 224 | 176,91×10 -3 | 30,27 |

| SFH-260G | 8000 | 2.9 | 1 (On one side) | ±1,4 | 3400 | 5390000 | 306 | 433,47×10 -3 | 53.11 |

*Max. Rotation speed does not take into account dynamic balance.

*Moment of inertia and mass measured for maximum bore diameter.

[Dimensions] SFH-□G

| Model | d1, d2 | D | N | L | LF | LS | S | F | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pilot drill hole | Minimum. | Max. | ||||||||||

| SFH-150G | 20 | 22 | 70 | 152 | 104 | 182 | 45 | 70 | 11 | 5 | 94 | 12-M8×36 |

| SFH-170G | 25 | 28 | 80 | 178 | 118 | 218 | 55 | 80 | 14 | 6 | 108 | 12-M10×45 |

| SFH-190G | 30 | 32 | 85 | 190 | 126 | 260 | 65 | 100 | 15 | 10 | 116 | 12-M12×54 |

| SFH-210G | 35 | 38 | 90 | 210 | 130 | 290 | 75 | 110 | 15 | 8 | 124 | 12-M16×60 |

| SFH-220G | 45 | 48 | 100 | 225 | 144 | 335 | 90 | 115 | 20 | -2 | 132 | 12-M16×60 |

| SFH-260G | 50 | 55 | 115 | 262 | 166 | 391 | 100 | 145 | 23 | 11 | 150 | 12-M20×80 |

* Pilot holes must be drilled into the part. See standard borehole drilling standards for information on borehole drilling.

*If you require a product with an LS size other than the size listed above, please contact Miki Pulley with your required size [mm]. Please contact Miki Pulley for support if LS ≧ 1000.

* The nominal diameter of a bored bolt is equal to the quantity minus the nominal diameter of the screw thread multiplied by the nominal length.

[Size for vertical applications with Max. Size LS] SFH-□G-□K-□K

| Model | LS [mm] |

|---|---|

| SFH-150G | 1100 |

| SFH-170G | 800 |

| SFH-190G | 900 |

| SFH-210G | 2000 |

| SFH-220G | 1900 |

| SFH-260G | 2500 |

*When considering vertical use and LS dimensions larger than those in the table above, refer to Miki Pulleys.

[Specifications] SFH-□G-□K-□K

| Model | Rated torque [N・m] | False | Max. rotation speed [min -1] | Torsional stiffness ([N・m]/rad) | Axial stiffness[N/mm] | Moment of inertia [kg・m 2] | Weight[kg] | ||

|---|---|---|---|---|---|---|---|---|---|

| Song song [mm] | Angle [°] | Shaft [mm] | |||||||

| SFH-150G | 1000 | 1.4 | 1 (On one side) | ±0,8 | 5900 | 750000 | 122 | 34,41×10 -3 | 12,96 |

| SFH-170G | 1300 | 1.6 | 1 (On one side) | ±1,0 | 5100 | 1420000 | 112 | 72,09×10 -3 | 18:95 |

| SFH-190G | 2000 | 2.0 | 1 (On one side) | ±1,0 | 4700 | 1700000 | 122 | 98,15×10 -3 | 23.14 |

| SFH-210G | 4000 | 2.1 | 1 (On one side) | ±1,1 | 4300 | 2340000 | 254 | 137,53×10 -3 | 26,61 |

*Max. Rotation speed does not take into account dynamic balance.

*The moment of inertia and mass in the table are measured for maximum bore diameter.

[Size] SFH-□G-□K-□K

| Model | D | L | d1, d2 | N1, N2 | LF | LS | S | C | K | M | M1 | M2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFH-150G | 152 | 238 | 38, 40, 42, 45, 48, 50 | 108 | 65 | 70 | 11 | 8 | 94 | 12-M8×36 | 6-M8×60 | 3-M8 |

| 55, 56, 60, 65, 70 | 128 | |||||||||||

| SFH-170G | 178 | 254 | 38, 40, 42, 45, 48, 50 | 108 | 65 | 80 | 14 | 8 | 108 | 12-M10×45 | 6-M8×60 | 3-M8 |

| 55, 56, 60, 65, 70 | 128 | |||||||||||

| 75, 80 | 148 | |||||||||||

| SFH-190G | 190 | 290 | 38, 40, 42, 45, 48, 50 | 108 | 70 | 100 | 15 | 10 | 116 | 12-M12×54 | 6-M10×65 | 3-M10 |

| 55, 56, 60, 65, 70 | 128 | |||||||||||

| 75, 80, 85 | 148 | |||||||||||

| SFH-210G | 210 | 306 | 38, 40, 42, 45, 48, 50 | 108 | 73 | 110 | 15 | 10 | 124 | 12-M16×60 | 6-M10×65 | 3-M10 |

| 55, 56, 60, 65, 70 | 128 | |||||||||||

| 75, 80, 85, 90 | 148 |

*If you require a product with an LS size other than the size listed above, please contact Miki Pulley with your required size [mm]. Please contact Miki Pulley for support if LS ≧ 1000.

* The nominal diameter of each bolt and tap is equal to the quantity minus the nominal diameter of the screw thread multiplied by the nominal length. The quantities for the pressure bolt M1 and the loose screw hole M2 are the quantities for the shaft on one side.

[Combination of standard bore diameters]

| Model | Standard hole diameter d1, d2 [mm] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | |

| SFH-150G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| SFH-170G | 1100 | 1200 | 1250 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| SFH-190G | 1800 | 1900 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| SFH-210G | 1800 | 1900 | 2000 | 2150 | 2300 | 2400 | 2600 | 2650 | 2850 | 3100 | 3350 | 3600 | 3800 | ● | ● |

*Bore diameters marked with ● or numbers are supported as standard bore diameters.

*The bore diameter field contains numbers that are limited in the rated torque by the holding capacity of the shaft connection because of the small bore diameter. The numbers represent the rated torque value [N·m].

[Size for vertical applications with Max. LS size]

| Model | LS [mm] |

|---|---|

| SFH-150G | 1100 |

| SFH-170G | 800 |

| SFH-190G | 900 |

| SFH-210G | 2000 |

*When considering vertical use and LS dimensions larger than those in the table above, refer to Miki Pulleys.

[Standard hole drilling standards]

| Models comply with the old JIS standard (type 2) JIS B 1301 1959 | The models comply with the new JIS standard (H9) JIS B 1301 1996 | Model conforms to JIS C 4210 2001 engine standard | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal hole diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) | Nominal hole diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) | Nominal hole diameter | Bore diameter (d1, d2) | Keyway width (W1, W2) | Keyway height (T1, T2) | Set screw hole (M) |

| ToleranceH7 | ToleranceE9 | -- | -- | ToleranceH7 | ToleranceH9 | -- | -- | ToleranceG7, F7 | ToleranceH9 | -- | -- | |||

| 22 | 22 +0,021 0 | 7 +0,061 +0,025 | 25,0 +0,3 0 | 2-M6 | 10 p.m | 22 +0,021 0 | 6 +0,030 0 | 24,8 +0,3 0 | 2-M5 | -- | -- | -- | -- | -- |

| 24 | 24 +0,021 0 | 7 +0,061 +0,025 | 27,0 +0,3 0 | 2-M6 | 24H | 24 +0,021 0 | 8 +0,036 0 | 27,3 +0,3 0 | 2-M6 | 24N | 24 +0,028 +0,007 | 8 +0,036 0 | 27,3 +0,3 0 | 2-M6 |

| 25 | 25 +0,021 0 | 7 +0,061 +0,025 | 28,0 +0,3 0 | 2-M6 | 25H | 25 +0,021 0 | 8 +0,036 0 | 28,3 +0,3 0 | 2-M6 | -- | -- | -- | -- | -- |

| 28 | 28 +0,021 0 | 7 +0,061 +0,025 | 31,0 +0,3 0 | 2-M6 | 28 hours | 28 +0,021 0 | 8 +0,036 0 | 31,3 +0,3 0 | 2-M6 | 28N | 28 +0,028 +0,007 | 8 +0,036 0 | 31,3 +0,3 0 | 2-M6 |

| 30 | 30 +0,021 0 | 7 +0,061 +0,025 | 33,0 +0,3 0 | 2-M6 | 30 hours | 30 +0,021 0 | 8 +0,036 0 | 33,3 +0,3 0 | 2-M6 | -- | -- | -- | -- | -- |

| 32 | 32 +0,025 0 | 10 +0,061 +0,025 | 35,5 +0,3 0 | 2-M8 | 32H | 32 +0,025 0 | 10 +0,036 0 | 35,3 +0,3 0 | 2-M8 | -- | -- | -- | -- | -- |

| 35 | 35 +0,025 0 | 10 +0,061 +0,025 | 38,5 +0,3 0 | 2-M8 | 35H | 35 +0,025 0 | 10 +0,036 0 | 38,3 +0,3 0 | 2-M8 | -- | -- | -- | -- | -- |

| 38 | 38 +0,025 0 | 10 +0,061 +0,025 | 41,5 +0,3 0 | 2-M8 | 38H | 38 +0,025 0 | 10 +0,036 0 | 41,3 +0,3 0 | 2-M8 | 38N | 38 +0,050 +0,025 | +0,036 010 | 41,3 +0,3 0 | 2-M8 |

| 40 | 40 +0,025 0 | 10 +0,061 +0,025 | 43,5 +0,3 0 | 2-M8 | 40H | 40 +0,025 0 | 12 +0,043 0 | 43,3 +0,3 0 | 2-M8 | -- | -- | -- | -- | -- |

| 42 | 42 +0,025 0 | 12 +0,061 +0,025 | 45,5 +0,3 0 | 2-M8 | 42H | 42 +0,025 0 | 12 +0,043 0 | 45,3 +0,3 0 | 2-M8 | 42N | 42 +0,050 +0,025 | 12 +0,043 0 | 45,3 +0,3 0 | 2-M8 |

| 45 | 45 +0,025 0 | 12 +0,061 +0,025 | 48,5 +0,3 0 | 2-M8 | 45H | 45 +0,025 0 | 14 +0,043 0 | 48,8 +0,3 0 | 2-M10 | -- | -- | -- | -- | -- |

| 48 | 48 +0,025 0 | 12 +0,061 +0,025 | 51,5 +0,3 0 | 2-M8 | 48H | 48 +0,025 0 | 14 +0,043 0 | 51,8 +0,3 0 | 2-M10 | 48N | 48 +0,050 +0,025 | 14 +0,043 0 | 51,8 +0,3 0 | 2-M10 |

| 50 | 50 +0,025 0 | 12 +0,061 +0,025 | 53,5 +0,3 0 | 2-M8 | 50H | 50 +0,025 0 | 14 +0,043 0 | 53,8 +0,3 0 | 2-M10 | -- | -- | -- | -- | -- |

| 55 | 55 +0,030 0 | 15 +0,075 +0,032 | 60,0 +0,3 0 | 2-M10 | 55H | 55 +0,030 0 | 16 +0,043 0 | 59,3 +0,3 0 | 2-M10 | 55N | 55 +0,060 +0,030 | 16 +0,043 0 | 59,3 +0,3 0 | 2-M10 |

| 56 | 56 +0,030 0 | 15 +0,075 +0,032 | 61,0 +0,3 0 | 2-M10 | 56H | 56 +0,030 0 | 16 +0,043 0 | 60,3 +0,3 0 | 2-M10 | -- | -- | -- | -- | -- |

| 60 | 60 +0,030 0 | 15 +0,075 +0,032 | 65,0 +0,3 0 | 2-M10 | 60H | 60 +0,030 0 | 18 +0,043 0 | 64,4 +0,3 0 | 2-M10 | 60N | 60 +0,060 +0,030 | 18 +0,043 0 | 64,4 +0,3 0 | 2-M10 |

| 65 | 65 +0,030 0 | 18 +0,075 +0,032 | 71,0 +0,3 0 | 2-M10 | 65H | 65 +0,030 0 | 18 +0,043 0 | 69,4 +0,3 0 | 2-M10 | 65N | 65 +0,060 +0,030 | 18 +0,043 0 | 69,4 +0,3 0 | 2-M10 |

| 70 | 70 +0,030 0 | 18 +0,075 +0,032 | 76,0 +0,3 0 | 2-M10 | 70H | 70 +0,030 0 | 20 +0,052 0 | 74,9 +0,5 0 | 2-M10 | -- | -- | -- | -- | -- |

| 75 | 75 +0,030 0 | 20 +0,092 +0,040 | 81,0 +0,5 0 | 2-M10 | 75H | 75 +0,030 0 | 20 +0,052 0 | 79,9 +0,5 0 | 2-M10 | 75N | 75 +0,060 +0,030 | 20 +0,052 0 | 79,9 +0,5 0 | 2-M10 |

| 80 | 80 +0,030 0 | 20 +0,092 +0,040 | 86,0 +0,5 0 | 2-M10 | 80H | 80 +0,030 0 | 22 +0,052 0 | 85,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

| 85 | 85 +0,035 0 | 24 +0,092 +0,040 | 93,0 +0,5 0 | 2-M12 | 85H | 85 +0,035 0 | 22 +0,052 0 | 90,4 +0,5 0 | 2-M12 | 85N | 85 +0,071 +0,035 | 22 +0,052 0 | 90,4 +0,5 0 | 2-M12 |

| 90 | 90 +0,035 0 | 24 +0,092 +0,040 | 98,0 +0,5 0 | 2-M12 | 90H | 90 +0,035 0 | 25 +0,052 0 | 95,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

| 95 | 95 +0,035 0 | 24 +0,092 +0,040 | 103,0 +0,5 0 | 2-M12 | 95H | 95 +0,035 0 | 25 +0,052 0 | 100,4 +0,5 0 | 2-M12 | 95N | 95 +0,071 +0,035 | 25 +0,052 0 | 100,4 +0,5 0 | 2-M12 |

| 100 | 100 +0,035 0 | 28 +0,092 +0,040 | 109,0 +0,5 0 | 2-M12 | 100H | 100 +0,035 0 | 28 +0,052 0 | 106,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

| 115 | 115 +0,035 0 | 32 +0,112 +0,050 | 125,0 +0,5 0 | 2-M12 | 115H | 115 +0,035 0 | 32 +0,052 0 | 122,4 +0,5 0 | 2-M12 | -- | -- | -- | -- | -- |

* The positions of the set screw and the keyway are not on the same plane.

* Screw set included with product.

* Positioning accuracy for keyway milling is determined by eye.

* Contact Miki Pulleys when the keyway requires positioning accuracy for a specific flange shaft.

* Refer to the technical documentation at the end of this volume for standard dimensions for borehole drilling in addition to those given here.

[Set screw position]

| Model | Distance from edge[mm] |

|---|---|

| SFH-150 | 15 |

| SFH-170 | 20 |

| SFH-190 | 25 |

| SFH-210 | 30 |

| SFH-220 | 35 |

| SFH-260 | 40 |

Related products

| SFH-150S | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-170S | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-190S | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-210S | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-220S | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-260S | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-150G | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-170G | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-190G | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-210G | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-220G | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

| SFH-260G | Couplings SFH Models | Coupling the SFH model | Miki Pulley |

See more technical documents here

See more technical products here

Link FaceBook Jon&Jul VietNam