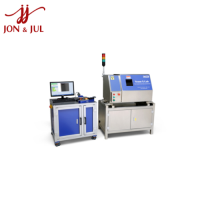

ADER-C6000 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Monitoring System

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

ADER-C6000 CanNeed Vietnam

The ADER-C6000 automatic enamel gauge is a fully digital device designed for automated, hands-free operation. It measures the enamel coating's thickness, coverage, and electrical current inside beverage cans. An uneven enamel layer can cause the product inside to corrode the metal material, affecting both quality and shelf life. This device uses fully automated testing technology, improving efficiency and reducing human errors. It has become a standard tool for evaluating can quality in the can manufacturing industry.

Key Features of ADER-C6000 CanNeed Vietnam:

- Automatic alignment and measurement in just 1 second.

- Equipped with a Golden Lens® camera to prevent peripheral light interference and ensure high resolution.

- Compatible with SPC and connected to Mitutoyo Digital Indicator data.

- Powered via a computer's USB port, no additional power source needed.

- Supports seam tightness measurement.

- Offers 5 overlap calculation formulas for user selection.

- Resolution of 0.001mm, accuracy of 0.005mm.

- Zoom feature for precise positioning of measurement lines.

- Includes a noise-canceling saw to protect user hearing.

- Customizable report generation.

Specifications:

- Power Source: Via USB port of the computer.

- Interface: RS 232 C.

- Resolution: 0.001mm.

- Accuracy: 0.005mm.

- Can Diameter: 52-127 mm, adjustable to 200 mm.

- Dimensions: L400 x W200 x H150 mm.

Applications of ADER-C6000 CanNeed Vietnam:

- Measuring enamel coating on cans in the food packaging industry.

- Checking seam tightness and quality in beverage production.

- Verifying the accuracy of seams on aluminum and steel cans.

- Testing can durability and safety in packaging.

- Supporting production data analysis in the food and beverage industry.

Benefits of ADER-C6000 CanNeed Vietnam:

- Fully automates the measurement process, saving time and effort.

- Minimizes human error, increasing accuracy.

- Easy data management with an integrated database system.

- Data can be exported in Excel format, flexible for reporting.

- Ensures production quality standards, enhancing efficiency.