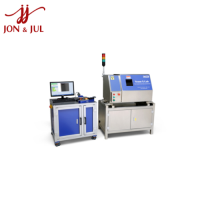

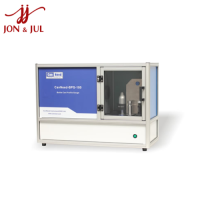

FMS-2000 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Monitoring System

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

FMS-2000 CanNeed Vietnam

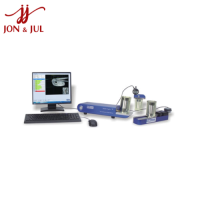

The FMS-2000 is an Automatic Front End Measure System developed by CanNeed. It measures the bottom depth, can height, and wall thickness (upper and middle) of two-piece cans. With its modern design, this system can test various can sizes without needing to change clamps, making it suitable for post-production inspection processes.

Key Features of FMS-2000 CanNeed Vietnam:

- Automated measurements save time and minimize human error.

- Accommodates samples of different diameters and heights without needing to change clamps.

- Accurately detects wall thickness transition points in cans.

- Vertical measurement ensures accurate can height and bottom depth readings.

- Advanced sensors ensure high precision and repeatability.

- Fast, efficient, and accurate measurements to enhance productivity.

- Durable, easy to operate, and convenient to maintain.

- Hard alloy probes ensure long-lasting durability.

- Components meet high international quality standards.

- Automatic data saving and result export via RS232 port.

- Safety-locked protective door prevents injuries during inspection or maintenance.

Specifications:

- Sample: Two-piece cans

- Sample size: Diameter: 50 mm - 57 mm; Height: 88 mm - 190 mm

- Measurement items: Bottom depth, can height, wall thickness

- Resolution: Bottom depth: 0.01 mm; Can height: 0.01 mm; Wall thickness: 0.001 mm

- Air supply: 6 bar

- Data output: RS232C

- Power supply: 220V/50Hz

- Dimensions: 720x570x900 mm

- Weight: 75 kg

Applications of FMS-2000 CanNeed Vietnam:

- Inspects two-piece can dimensions post-production.

- Accurately measures bottom depth and can height.

- Ensures can quality and durability in beverage manufacturing plants.

- Supports product quality management to international standards.

- Analyzes and improves the can production process.

Benefits of FMS-2000 CanNeed Vietnam:

- Automated measurements save time and reduce human errors.

- Measures multiple can sizes without changing clamps.

- Enhances inspection efficiency and ensures accurate results.

- Durable system, easy to operate and maintain.

- Automatically connects to computers or SPC systems for result storage and export.