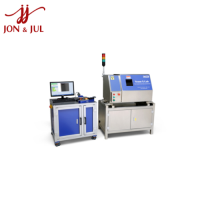

Seam-X-On-Line-T CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Seam Scanner

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

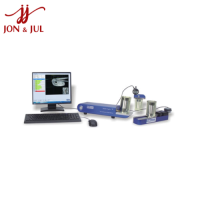

Seam-X-On-Line-T CanNeed Vietnam

The Seam-X-On-Line-T is a full automatic seam scanner that uses non-destructive testing methods to inspect can weld parameters. This device is designed for direct installation on production lines, providing fast and accurate sample inspection and measurement. It can measure cans made of various materials, from aluminum to tin, ensuring precise and consistent results.

Key Features of Seam-X-On-Line-T CanNeed Vietnam:

- Unsupervised operation reduces labor costs.

- No sample waste, environmentally friendly.

- High accuracy, preventing manual errors.

- High-speed and high-frequency sampling reduces defective products.

- Accurate detection of faulty welds.

- Automatically removes defective products.

- Excellent repeatability and reproducibility.

- Comprehensive 360° scanning.

- Patented technology.

- X-ray safety standard compliance.

- Safe operation, minimizing injury risks.

- Easy calibration with provided calibration samples.

- Compatible with various can sizes and specifications.

- Automatic pass/fail evaluation.

- Optional weld recognition for 3-piece cans.

- Automatic storage of measurement data in SPC standard.

Specifications:

- Can Material: Aluminum & Aluminum; Tin & Tin (can body and lid)

- Can Sizes: Diameter 200 (50mm) - 211 (67mm), Height ≤ 168mm

- Measurement Targets: Weld length, can body hook, lid hook, weld overlap, % overlap, weld gap, % body hook, % lid hook

- Units: Inch, mm

- Languages: English & Chinese

- Accuracy: ±0.01 mm

- Resolution: 0.001 mm

- Outputs: Ethernet, ASCII, TXT, SQL, DBI

- Power Supply: 100-240VAC, 50/60 Hz

- Dimensions: Length 1400×Width 1500×Height 2000 mm

- Air Supply: 0.4 – 0.6 MPa

- Weight: Approx. 2000kg

Applications of Seam-X-On-Line-T CanNeed Vietnam:

- Weld measurement for aluminum and tin cans.

- Integrated into production lines for quality control.

- Ideal for beverage can manufacturing plants.

- Suitable for food can production facilities.

- Supports weld inspection in automated packaging processes.

Benefits of Seam-X-On-Line-T CanNeed Vietnam:

- Increased accuracy and production efficiency.

- Minimizes product defects and optimizes quality.

- Saves labor costs and sample materials.

- Protects operators and the environment.

- A fully automated system with data storage and analysis capabilities.