Canneed-DER-400M Máy đo chỉ số lên men

Price: Contact

Brand: CanNeed

Category: Testing and Measuring Equipment

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

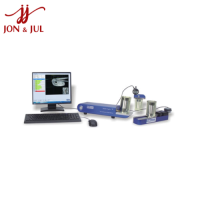

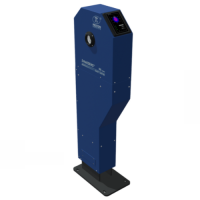

Canneed-DER-400M CanNeed Vietnam fermentation index meter

Canneed-DER-400M Fermentation Index Meter CanNeed Vietnam

CanNeed DER-400M The CanNeed Fermentation Index Meter is an advanced instrument designed to measure the fermentation index in metal packaging products, especially in the food and beverage industry. It features an improved electronic design that enhances sensitivity, reliability, and accuracy, surpassing previous models. The CanNeed DER-400M not only easily detects exposed metal, but also ensures high durability with good corrosion resistance from the upgraded body and durable film-coated buttons.

Outstanding features

- Improved Detection: The DER-400M detects exposed metal more easily thanks to improved electronic design, enhancing sensitivity and accuracy.

- Advanced electronic design: Ensures high reliability and accuracy, with resolution as accurate as 0.01 mA.

- Superior corrosion resistance: The body is upgraded with good corrosion resistance and durable film-coated buttons, suitable for factory environment.

- Flexible measurement modes: Can operate in standard 4-second mode, continuous mode or custom measurement time.

- Voltage polarity reversal function: Helps detect exposed metal more easily by creating air bubbles at the defect location.

Specifications

- Sample Type: 2-piece and 3-piece boxes, spray boxes and other types of box heads

- Measuring range: 0 to 500 mA

- Resolution: 0.01 mA

- Accuracy: ± 2%

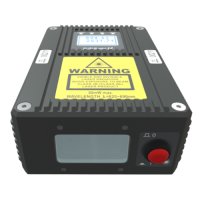

- Test voltage: 6.3 VDC

- Power supply: AC 115V/230V converted to DC 9V

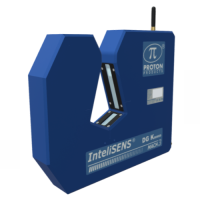

- Display unit size: 162 x 200 x 80 mm (W x D x H)

- Box holder size: 210 x 228 x 250 mm (W x D x H)

- Weight: 4 kg

- Communication port: RS232 serial output

Application of the device

- Food and beverage packaging quality inspection: Ensure enamel coating meets quality standards, reducing the risk of corrosion.

- Aerosol industry: Evaluation of enamel coatings on aerosol cans and other metal packaging.

- Metal packaging production: Helps detect defects in enamel coatings in a timely manner during production.

- In-factory quality control: Monitor and inspect the enamel layer to maintain high quality standards.

- Periodic maintenance and inspection services: Used in periodic maintenance and inspection activities to ensure that the packaging is not damaged.

Benefits of use

- Increased accuracy: Ensures timely detection of defects in the enamel layer, improving product quality.

- Efficient Operation: Easy-to-use device with flexible measurement modes saves time and effort.

- Durable and Reliable: With a corrosion-resistant and durable design, the DER-400M has a long life, suitable for harsh production environments.

- Convenient voltage polarity reversal function: Helps detect defects more easily with air bubbles generated at exposed locations.

- Easy integration with data systems: RS232 port allows connection to remote computers, printers or data collection devices, supporting efficient information management.

See more technical products here