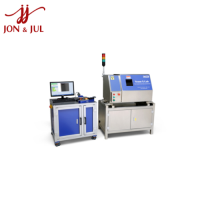

ACSS-1000 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Test & Analyze

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

ACSS-1000 CanNeed Vietnam

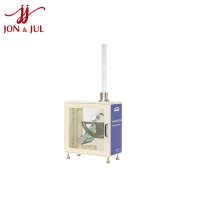

The CanNeed-ACSS-1000 Automatic Anti-noise Seam Saw, developed by CanNeed, is a specialized device for quickly cutting can seams for measurement and inspection purposes. With automatic operation and noise-reduction features, this equipment enhances work efficiency while ensuring optimal safety for users.

The machine is designed to handle up to 12 cans at a time, meeting the demand for quick and convenient quality checks.

Key Features:

- Fully Automatic Cutting: Minimizes user intervention, boosting work efficiency.

- Safe and User-Friendly: Users only need to place the cans, reducing injury risks during the cutting process.

- High Stability, Easy Maintenance: Equipped with durable carbide blades to ensure precise cuts without deforming or leaving uneven edges.

- Smart Design: Easy-to-clean pull-out tray for quick metal scrap collection, requiring minimal regular maintenance.

- Flexible Adaptability: Quickly adjustable positioning sleeves, suitable for cans of varying heights.

Applications of ACSS-1000 CanNeed Vietnam:

- Quality seam inspections in the beverage production industry.

- Applications in laboratory research and can packaging development.

- Assisting in cutting can samples for structural and material analysis.

- Quality checks of can seams in the canned food industry.

- Integration into quality inspection lines in can manufacturing plants.

Specifications:

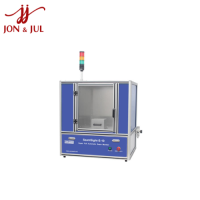

- Sample Diameter Range: 202-211 (52-65 mm)

- Sample Height Range: 88-190 mm

- Power Supply: 220V/50Hz

- Power Consumption: 300W

- Machine Dimensions: 730 mm (L) × 730 mm (W) × 1220 mm (H)

- Weight: 80 kg