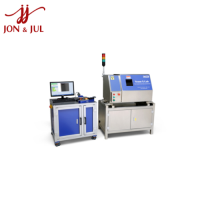

Seam-X-Line CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Seam Scanner

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

Seam-X-Line CanNeed Vietnam

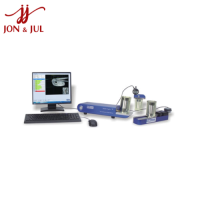

The Seam-X-Line X-Ray Automatic Seam Scanner uses a non-invasive measurement technique to evaluate seam quality. It is ideal for assessing aluminum cans, steel cans, aluminum-iron composite cans, and more. When integrated with a conveyor system, it allows for automatic sampling from the production line, making it suitable for both laboratory and production settings.

Key Features of the Seam-X-Line CanNeed Vietnam:

- Non-invasive measurements that eliminate sample waste

- Environmentally friendly, reducing pollution and minimizing handling costs

- High sampling frequency, which decreases instances of inferior products

- Cost-efficient due to high sampling rates

- Tracks chucks related to defective products

- Comprehensive 360-degree scanning for thorough measurements

- Versatile enough to handle various can types

- Enhanced accuracy in measurements

- Reduces errors associated with manual measurements

- Built for durability

- Meets international safety standards

Specifications:

- Designed for laboratory and production use

- Sampling modes: Seam-X-Lab (manual) and Seam-X-Line (automatic)

- Features automatic door operation

- Capable of automatic measurement and evaluation

- 360-degree scanning ensures no blind spots

- Measuring speed: one can every minute

- Production capacity: approximately 1320 cans per day based on 22 hours of operation

- Reliable for continuous monitoring

- Measurement accuracy: 0.01 mm

- Dimensions of Seam-X-Lab: 900 x 550 x 650 mm

- Weight of Seam-X-Lab: 300 kg

- Dimensions of Seam-X-Line: 3000 x 2000 x 2200 mm

- Weight of Seam-X-Line: 500 kg

Applications of the Seam-X-Line CanNeed Vietnam:

- Quality Control: Ensures the integrity of seams in aluminum and steel cans during production.

- Laboratory Testing: Ideal for research and development environments requiring precise measurements.

- Production Line Integration: Automatically samples and evaluates seams directly from the production conveyor.

- Material Analysis: Suitable for testing aluminum-iron composite cans and other materials.

- Regulatory Compliance: Helps manufacturers meet safety and quality standards in packaging.

Benefits of the Seam-X-Line CanNeed Vietnam:

- Non-Invasive Measurements: Prevents waste by eliminating the need for destructive testing.

- Cost Efficiency: Reduces handling and environmental costs through automated processes.

- Enhanced Accuracy: Provides precise measurements, minimizing errors compared to manual methods.

- Versatile Compatibility: Works with a variety of can types, making it adaptable for different production needs.

- Continuous Monitoring: Reliable for ongoing quality assessments, ensuring consistent product quality.