MDER 10 Canneed Viet Nam

Price: Contact

Brand: CanNeed

Category: digital enamel measuring machine

Supplier: Jon&Jul Việt Nam

Origin: China

Ứng dụng sản phẩm: Electronic

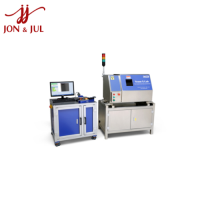

MDER 10 Canneed Vietnam digital enamel evaluation machine

Introducing the MDER 10 Canneed Vietnam digital enamel evaluation machine

The MDER-10 multi-station digital enamel evaluation machine is a specialized device used in the paint and enamel industry to evaluate the quality of enamel and paint on multi-station heads automatically. and exactly.

This is a modern and advanced tool, capable of measuring and analyzing a variety of technical parameters of enamel and paint layers on product surfaces.

To meet the needs of testing multiple terminals at the same time, CanNeed designed the MDER-10 and MDER-20 Multi-Station Digital Enamel Evaluators for terminals. MDER-10 can complete the current testing of 10 heads in 4 seconds.

If connected to two ten-hole fixed holders, it can test 10 heads at the same time. The diameter of the heads is 50-99mm.

Place the ends into the opening of the ten-hole fixing bracket. After pressing the ends, turn the ten-hole fixing brackets over.

The current values (mA) of each end as well as the maximum current value and average value can be read in 4 seconds.

If any test fails due to poor connection between contacts, the corresponding position number of the terminals can be displayed on the screen.

Data can be transmitted to a computer via RS 232 C.

Features of the MDER 10 Canneed Vietnam digital enamel evaluation machine

- Multi-station feature : MDER-10 is designed to operate simultaneously on multiple evaluation heads, allowing simultaneous evaluation of many product samples effectively and saving time.

- Accuracy and reliability : This device uses advanced sensor technology and software to provide accurate and reliable measurement data on enamel and paint thickness, surface roughness, gloss and other properties of the coating.

- Diversity of measurement parameters : MDER-10 is capable of measuring many different technical parameters of enamel and paint such as thickness, hardness, gloss, roughness, adhesion and other important criteria. to evaluate the quality and uniformity of the coating.

- Automation and ease of use : The device is controlled by a digital system and has a user-friendly interface, allowing users to easily set up and operate measurement procedures automatically and convenient.

- Widely used in industry : The MDER-10 machine is applied in paint and enamel factories, metal, wood, plastic processing companies and many other industries to check and evaluate quality. finished product.