AOBMS-2020 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Monitoring System

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

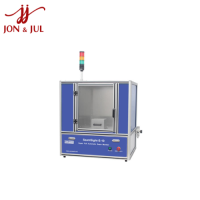

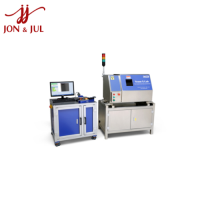

AOBMS-2020 CanNeed Vietnam

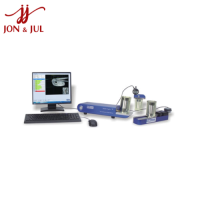

The AOBMS-2020 Automatic Back End Measurement System from CanNeed Vietnam is an automated measurement system for the final stage of the can production process, offering unattended operation. The system uses non-contact laser technology to automatically measure parameters such as: seam width (C), can height (H), inner diameter (B), bottom dome depth (D), seam angle (E), flange length (J), post-formed diameter (R), post-formed height (F), and minimum bottom diameter (G) for two-piece cans. This machine applies fully automated inspection technology, enhancing efficiency and minimizing human errors. It is a standard for can quality evaluation in the can manufacturing industry.

Key Features of AOBMS-2020 CanNeed Vietnam:

- Non-contact laser measurement technology with an accuracy of ±0.01mm.

- Dual laser heads conduct multi-point measurements simultaneously, with a measurement speed of up to 15 seconds per can.

- Compatible with various can sizes, with quick changeover without component replacement.

- Multi-channel sampling system allows for multiple cans to be measured simultaneously.

- Automatic calibration and customizable calibration time and points as needed.

- Data is automatically stored and transferred to the SPC system.

- Easy-to-use database management software for data lookup and reporting.

- Customizable report formats to suit business requirements.

- Integrated HD camera supports remote maintenance.

- Durable, user-friendly, and easy to maintain.

Specifications:

- Accuracy: ±0.01mm

- Measurable can sizes: Two-piece cans with diameters of 202, 204 & 211; can heights from 87-190mm

- Air supply: > 4bar

- Material: Aluminum alloy frame

- Power supply: 220V/50Hz

- Dimensions: Length 3158mm x Width 1000mm x Height 1900mm

Applications of AOBMS-2020 CanNeed Vietnam:

- Measuring can parameters in beverage can manufacturing plants.

- Inspecting can quality before entering the packaging line.

- Applied in product can quality standard inspections.

- Supporting SPC quality management systems in industry.

- Checking the durability and safety of cans during production.

Benefits of AOBMS-2020 CanNeed Vietnam:

- Fully automates the inspection process, minimizing human error.

- Saves time and labor costs with automated measurement processes.

- High accuracy ensures cans meet quality standards.

- Easy measurement data management with modern software.

- Remote maintenance support reduces machine downtime.