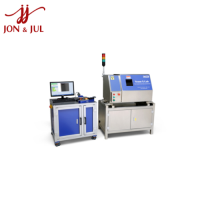

ASST-Line-1000 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Seal Tester

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

ASST-Line-1000 CanNeed Vietnam

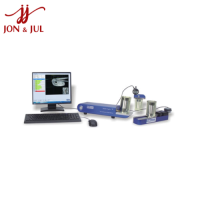

The CanNeed ASST-Line-1000 automatic leak tester is an efficient solution for testing the tightness of finished products. This fully automatic machine requires no supervision, ensuring stringent control over sealing performance and preventing gas leakage after packaging. The ASST-Line-1000 is ideal for the beverage industry and complies with international testing standards.

Key Features of ASST-Line-1000 CanNeed Vietnam:

- Multi-stage programmable system, capable of setting up to 8 pressure and time stages.

- Digital display and data storage with RS232 port for automatic data export to SPC systems.

- Equipped with two speed control valves for compression rate adjustment.

- Multiple safety measures integrated.

- High sensitivity with superior accuracy.

- Utilizes CO2 from a gas cylinder for pumping and pressurizing.

- Stainless steel 304 frame with interlocking safety design.

- Automatic inspection and sample rejection function, increasing work efficiency.

- Unattended testing mode, ensuring high automatic accuracy.

Specifications:

- Measurement Range: 0—1.2Mpa; Accuracy: 0.1Kpa

- Sample Range: Diameter: 60-110mm; Height: 100-350mm

- Testing Speed: 10 seconds/bottle, one station

- Sample Feeding Method: Conveyor belt

- Sample Capacity: 10 units (D65mm); NG area can hold up to 5 units (D65mm)

- Power Supply: AC220V 50Hz, air pressure 1.2-1.4Mpa

- Environment Conditions: Indoors, relative humidity ≤ 85%, temperature: 0℃-40℃

Applications of ASST-Line-1000 CanNeed Vietnam:

- Leak testing of beverage bottles and plastic bottles.

- Evaluating sealing quality during PET bottle production.

- Ensuring the tightness of bottle packaging and preventing CO2 gas leakage.

- Testing bottled products in the food and beverage industry.

- Monitoring the sealing and quality of automatically packaged products.

Benefits of ASST-Line-1000 CanNeed Vietnam:

- Labor savings thanks to the fully automated testing process.

- High precision, reducing the risk of defective products.

- Increased production efficiency with fast testing speeds.

- Ensures safety with interlock design and multiple protective measures.

- Automatic data integration into management systems, optimizing production processes.