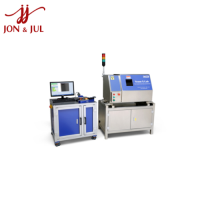

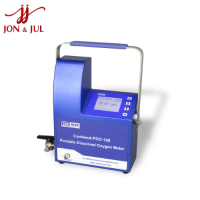

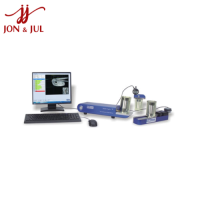

ASTG-1000 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Test & Analyze

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

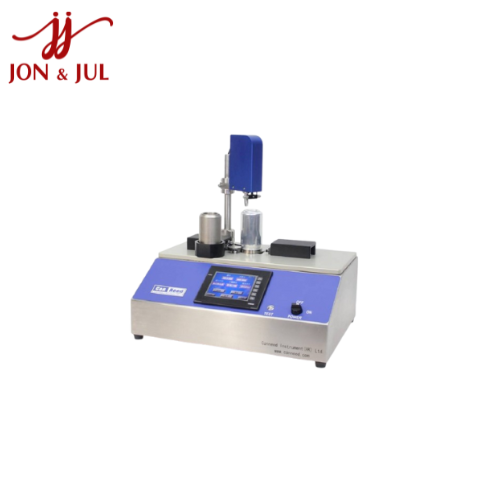

ASTG-1000 CanNeed Vietnam

The CanNeed ASTG-1000 integrates advanced 360° automatic measurement technology to detect irregularities in weld seams – the primary cause of gas leakage in cans. With high precision, fast measurement speed, and direct data export capability, the ASTG-1000 is the ideal choice for the canned beverage production industry.

Key Features:

- Automatic 360° weld seam thickness measurement with up to 50 measuring points.

- Integrated automatic can rotation function for multi-point measurement.

- Digital measurement results displayed on a touch screen for easy monitoring and processing.

- RS232 port support for direct data export to computers for SPC analysis.

- Optional can height measurement functionality to meet diverse inspection requirements.

Applications of ASTG-1000 CanNeed Vietnam:

- Inspecting can weld seams to prevent gas leakage.

- Ensuring weld seam quality in the can production process.

- Detecting and identifying irregularities in weld seams.

- Supporting the analysis and improvement of can designs.

- Combining with SPC software to optimize quality control processes.

Specifications:

- Measurement range: 0-6mm

- Accuracy: 0.01mm

- Suitable samples: Can body 211 – lid 206/202, or other types of cans.