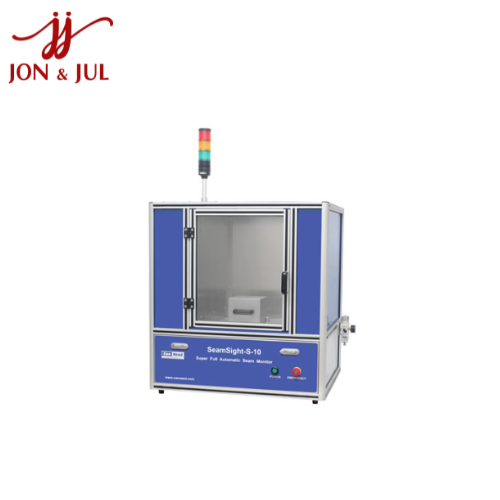

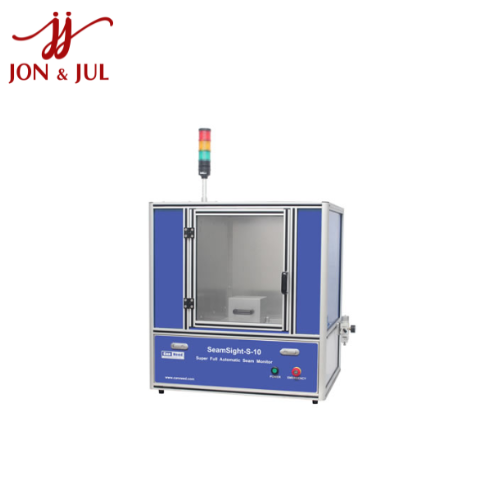

SeamSight-S-10 CanNeed Vietnam

Price: Contact

Brand: CanNeed

Category: Test & Analyze

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Automation equipment

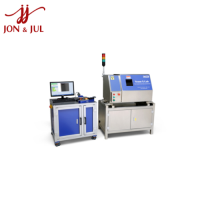

SeamSight-S-10 CanNeed Vietnam

The SeamSight-S-10 Super Automatic Seam Monitor from CanNeed integrates three functions: automatic can cutting, automatic seam inspection, and digital data collection. This product provides an efficient and safe alternative to traditional manual inspection methods, saving time and minimizing labor risks.

Key Features:

- Inspection Capacity: 1 can per operation.

- Innovative Design: Automatically cuts and inspects cans, minimizing operator intervention.

- High Safety Standards: Eliminates risks of injuries caused by manual cutting.

- Exceptional Efficiency: Completes the entire inspection process quickly and accurately.

- Premium Quality: Utilizes Golden Lens® technology for clear and sharp imaging.

- Easy Maintenance: Pull-out tray simplifies the cleaning of metal shavings.

- Customizable Features: Supports 5 overlap calculation formulas and flexible reporting formats.

- High Precision: Resolution of 0.001mm and accuracy of 0.005mm.

Applications of SeamSight-S-10 CanNeed Vietnam:

- Quality inspection of seams on food and beverage cans.

- Evaluating seam durability in industrial production.

- Research and development of new packaging products.

- Supporting quality control (QC) processes at manufacturing plants.

- Training and teaching seam inspection methods.

Specifications:

- Resolution: 0.001mm

- Accuracy: 0.005mm

- Magnification: 60× (overview magnification), 180× (cut-line magnification)

- Supported Can Sizes: 113, 202, 206, 209 (customizable upon request)

- Video Equipment: Golden Lens®