MHD – 7TH AXIS TRACK SYSTEM Hệ thống theo dõi 7 trục Hepcomotion

Price: Contact

Brand: Hepcomotion

Category: Actuator

Supplier: jonjul

Origin: UK

Ứng dụng sản phẩm: accessory, Automation equipment, Electronic, Industry, Mechanical

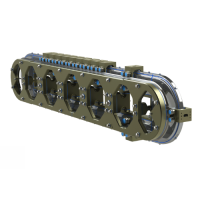

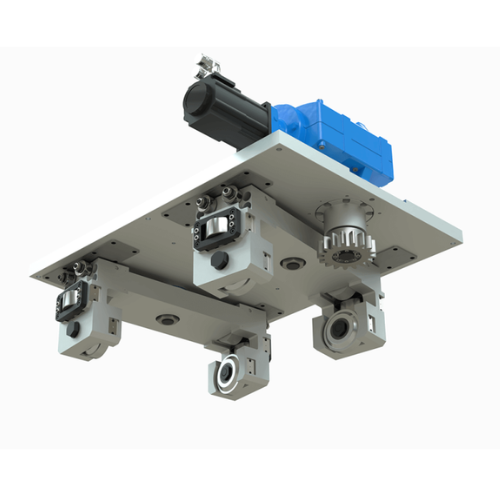

MHD – 7TH AXIS TRACK SYSTEM Hepcomotion 7-axis tracking system

Introducing MHD – 7TH AXIS TRACK SYSTEM Hepcomotion 7-axis tracking system

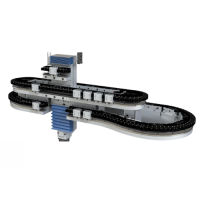

Hepco's Maximum Load 7th Axis (MHD) tracking system combines linear and curved motion, expanding the range of motion for 7th axis robots, allowing for more flexible and dynamic movements.

Curved 7th axis robot transfer – This unique development allows the 7th axis robot transfer system to move around curves and straight sections, providing automation opportunities that were previously impossible can be done.

Freely configurable layout – By combining curved and straight segments, virtually unlimited 2D shape track layouts can be created to meet the exact requirements of the application.

Flexible design – Oval, rectangular, round, 'J', 'U' and 'S' shapes available as standard.

Closed and open circuits can be specified.

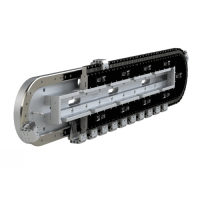

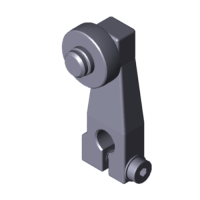

Different Radius Tracks – The unique swerving mechanism means that a carriage can move around curves of different radii and different directions on the same track system.

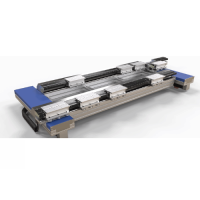

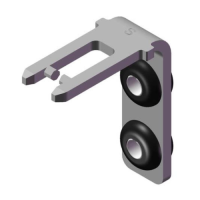

Caters for high moment loads – Large carriage size provides stability, high moment load capacity and can withstand forces created by E-stop conditions.

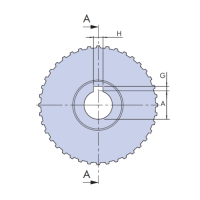

Durable – High-capacity double tapered roller bearings provide precise, durable movement with little friction.

Bearings are sealed for life, making them resistant to debris.

Low maintenance – Bearing block lubricants coat each bearing with a layer of oil to maximize longevity.

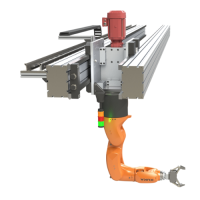

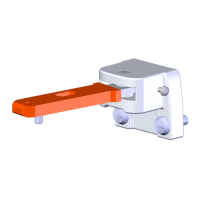

Drive Flange & Gear Motor – The integrated drive flange assembly allows for a gear motor to be installed to drive the carriage, while leaving a large base for mounting a robot or other equipment.

See more technical documents here

See more technical products here

Link FaceBook Jon&Jul VietNam

-------------

Communications

Phone number: 0348097237

Email: Tu@jon-jul.com

Address: No. 4, Street 14, Highway 13, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City, Vietnam