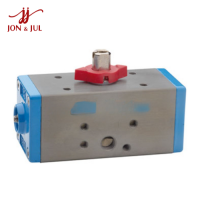

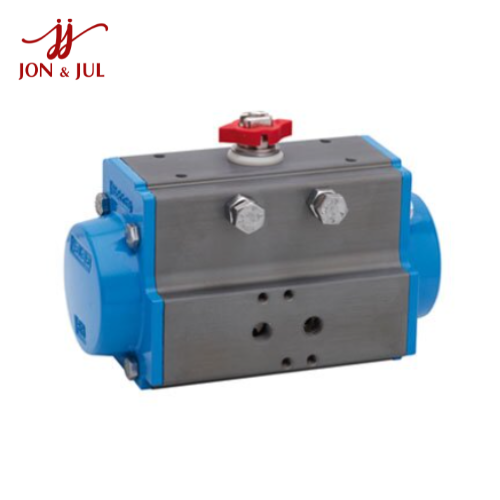

MOD 85 Valbia Việt Nam

Price: Contact

Brand: Valbia

Category: Actuator

Supplier: Jon&Jul Việt Nam

Origin:

Ứng dụng sản phẩm: Mechanical

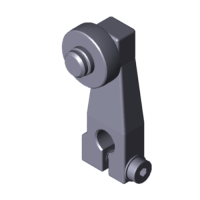

Pneumatic Actuators SERIES 82 MOD 85 Valbia Vietnam

Introducing Pneumatic Actuators SERIES 82 MOD 85 Valbia Vietnam

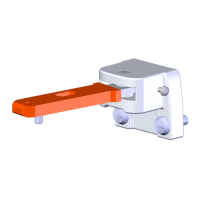

The Valbia 82 Series MOD 85 pneumatic actuator is one of the leading products designed to provide efficient and sustainable solutions in valve automation.

With modern design and high quality, this product is suitable for many different industrial applications, from chemical, oil and gas, to water treatment and many other fields.

The 82 Series MOD 85 Valbia pneumatic actuators are widely used in industries

- Chemical and Pharmaceutical, ensuring accuracy and durability in harsh chemical environments.

- Oil and Gas, withstands high pressure and harsh environmental conditions.

- Water Treatment, used in clean water and wastewater treatment systems.

- Food and Beverage, ensuring hygiene and reliability in production.

Technical specifications Pneumatic actuator SERIES 82 MOD 85 Valbia Vietnam

- Torque, varies depending on specific model, suitable for many types of valves.

- Compressed Air Pressure, typically 2.5 to 8 bar.

- Operating Temperature, from -20°C to +80°C, depending on material and specific application.

- Body Material, usually made from aluminum alloy or stainless steel.

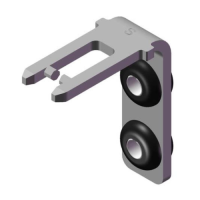

- Connection Standard, conforming to international standards such as ISO 5211.

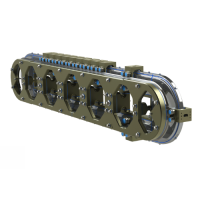

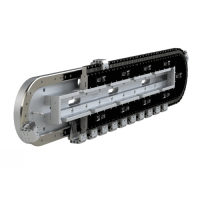

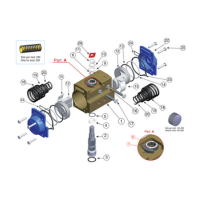

| Position | Part name | Material | Treatment | N.° pieces |

|---|---|---|---|---|

| 1 | Body | Extruded aluminium | Hard anodized | 1 |

| 2 | Anti-blowout pinion | Steel | Nickel plated | 1 |

| • 3 | O-ring | NBR/SILICONE/FKM | - | 1 |

| • 4 | Spacer ring | POM/AMODEL/STANYL/PEEK | - | 1 |

| • 5 | O-ring | NBR/SILICONE/FKM | - | 1 |

| • 6 | O-ring | NBR/SILICONE/FKM | - | 1 |

| 7 | Cam | Stainless steel | - | 1 |

| 8 | Spacer | POM/MINLON/PTFE/PEEK | - | 1 |

| • 9 | Ring under seeger -Spacer | POM/MINLON/PTFE/PEEK | - | 1 |

| 10 | Washer | Stainless steel | - | 1 |

| **11 | Snap ring | Steel | Nickel plated | 1 |

| 12 | Piston | Die cast aluminium | - | 2 |

| • 13 | O-ring | NBR/SILICONE/FKM | - | 2 |

| • 14 | Antifriction ring | POM/AMODEL/STANYL/PTFE/MINLON/PEEK | - | 2 |

| • 15 | Thrust block | POM-AMODEL-STANYL-DELRIN+MOS2/PEEK | - | 2 [4] |

| 16 | Stop bolt retaining nut | Stainless steel | - | 2 |

| 17 | Stop bolt | Stainless steel | - | 2 |

| 18 | External spring | Steel | Painted | See spring setting |

| ***19 | Central spring | Steel | Painted | See spring setting |

| 20 | Internal spring | Steel | Painted | See spring setting |

| 21 | Left end cap | Die cast aluminium | Painted | 1 |

| 22 | Right end cap | Die cast aluminium | Painted | 1 |

| 23 | End cap seats | NBR/SANTOPRENE/SILICONE/FKM/ME0020-70 | - | 2 |

| 24 | O-ring | NBR/SILICONE/FKM | - | 2 |

| 25 | End cap fixing screw | Stainless steel | - | 8 |

| 26 | Position indicator | Gomma termoplastica TPEThermoplastic rubber TPE | - | 1 |

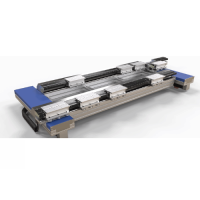

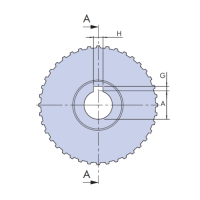

| AGAINST | DRILLING ISO 5211 | CH | A | B | C | D | E | F | G | H | Ø I | INC | L | M | N | O | P | Q | R | S | T ISO 7/1 | IN | øV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AGAINST. 85 | F05 - F07 | 17 | 240,5 | 106 | 47,5 | 58,5 | 125 | 20 | 145 | 15 | 35 | 22 | 80 | 30 | 19 | 42 | 70 | 50 | M6X8 | M8X12 | 1/8” | 42 | 29 |