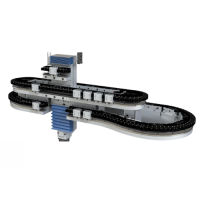

NLD 25 V3 LineDrive Netter Vibration LineDrive Conveyor System

Price: Contact

Brand: Netter Vibration

Category: Actuator

Supplier: Jon-Jul

Origin: Germany

Ứng dụng sản phẩm: accessory, Automation equipment, Electronic, Industry, Mechanical

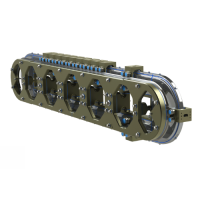

NLD 25 V3 LineDrive Netter Vibration conveyor system

Introduce

With traditional vibrating conveyor systems, the moving bulk material is "thrown" forward in a parabolic trajectory, which can damage or degrade the product.

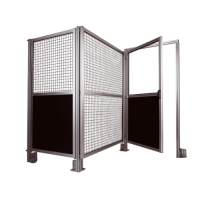

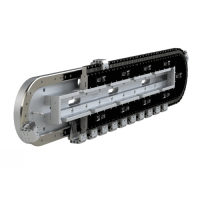

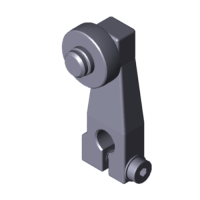

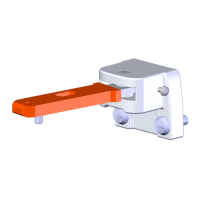

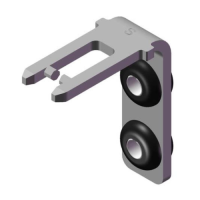

On the other hand, the Line Drive conveyor system uses a pneumatic linear actuator that causes the material to slide along the conveyor chute. The flow rate can be adjusted to the specific characteristics of the material being transported by pneumatic control. For conveyor systems longer than two meters, the chute is supported by a Line Drive unit. Pairing several Line Drive units allows for larger load transmission.

Principles of design and operation of NLD 25 V3 LineDrive Netter Vibration conveyor system

Traditional vibratory conveyor systems operate on the "thrown" principle.

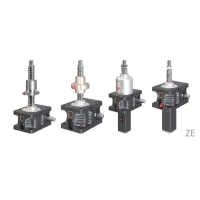

With the LineDrive conveyor principle, materials slide along the conveyor trough. This is done using a pneumatic linear actuator. The output of the conveyor can be adjusted to suit the specific characteristics of the material, which is conveyed by pneumatic adjustment.

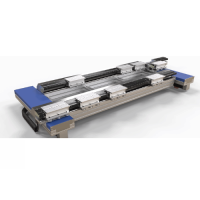

In longer conveyor systems (from around 2m), the chute is supported by a LineDrive support, larger loads can be conveyed by coupling several LineDrive push systems.

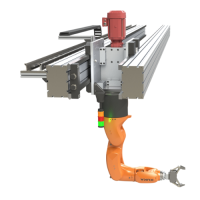

In addition to the standard versions, custom variants of the LineDrive series are also available and components are also supplied individually.

Operating conditions allow

Compressed air or Nitrogen (filter < 5µm)

Optimal operating pressure: 2 bar

Ambient temperature: 5 0 C - 60 0 C

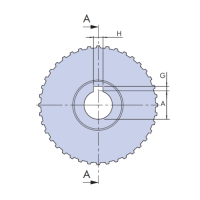

See more drawings here

See more technical documents here

See more technical products here

-------------

Communications

Phone number: 0348097237

Email: Tu@jon-jul.com

Address: No. 4, Street 14, Highway 13, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City, Vietnam