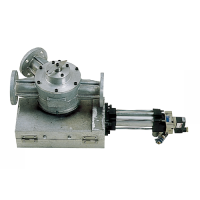

DP Suction Pressure Sensor Unit Bộ cảm biến áp suất hút Matsui VietNam

Price: Contact

Brand: Matsui

Category: Detect Fire Detector

Supplier: jonjul

Origin: Japan

Ứng dụng sản phẩm: accessory, Automation equipment, Electronic, Industry, Mechanical

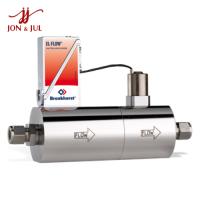

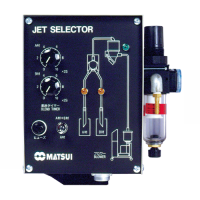

DP Suction Pressure Sensor Unit Matsui VietNam suction pressure sensor unit

Introducing DP Suction Pressure Sensor Unit Matsui VietNam suction pressure sensor

A new system sends signals converted from signals generated by detecting changes in vacuum pressure.

The DP detects the suction pressure generated for conveying and controls the volumetric feeding of raw materials.

Therefore, it is possible to convey materials without connecting signal wires.

If you attach DIGI-PECA, fixed quantity material can be transported without any signal cable even it is 40-50m away from the dryer (No wiring required).

When using another model, the same system can be used continuously by replacing the hose.

It is possible to build a system using existing standard loaders.

Basic operations

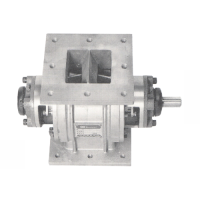

Level gauges on injection molding machines give a signal about material demand.

The conveying equipment's blower is next to the starter molding machine.

The transportation pipeline is depressurized.

The pressure sensor (DP-S) on the material side detects constant pressure.

The DIGI-PECA (DP-C2) controller generates control signals and receives output signals from the controller to operate the cutting device. Note 1) There are two types of output, time and count.

Choose one of the two. Note 2) DIGI-PECA can also change output according to the start-up time of the belt blower.

See more technical documents here

See more technical products here

Link FaceBook Jon&Jul VietNam

-------------

Communications

Phone number: 0348097237

Email: Tu@jon-jul.com

Address: No. 4, Street 14, Highway 13, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City, Vietnam